To provide nutrients to crops and plants more efficiently, it is necessary to produce biofertilizers. This technology makes it possible to improve the absorption of nutrients by plants thanks to the microorganisms they contain. However, its process is more complex than that of manufacturing of organic fertilizers. In addition to manufacturing, it is essential to focus on adding microorganisms. SO, how to produce organic fertilizers efficiently ? For that, there are different fertilizer machines, which allow you to easily and quickly produce powdered biofertilizers, in granules and liquid.

Settings

- Ability : 1 has 20 t/h

- Surface : 800 has 10 000 m²

- Products : poudre, pellets, liquid

- Addition of bacteria : azotobacters, phosphobactéries, bactéries silicatées, pseudomonas, actinomycètes, etc

- Application : Manure, straw, rice husk, biogas residues, sludge, etc.

What are the commonly used microorganisms in the manufacture of organic fertilizers??

As a professional fertilizer equipment factory, YUSHUNXIN will develop a business plan adapted to your actual conditions. Capacity is an essential element to take into account. So what equipment is used for a 20,000 t/year organic fertilizer production line?? It is generally advisable to operate the fertilizer preparation line in two shifts per day, for 10 hours per shift. It is therefore necessary to purchase organic fertilizer machines with a capacity of 3 at 4 t/h. For that, We recommend purchasing the following equipment:

Microbial composting inoculant

As its name suggests, microbial composting inoculant is widely used in the composting process of biofertilizers. It facilitates composting of manure and eliminates odors from animal waste. This microbial agent is generally a complex bacteria, notably photosynthetic bacteria, lactic acid bacteria, yeasts, of the actinomycètes, penicillium, trichodermas, etc.

Functional bacteria

Functional bacteria can be used after composting, because they are destroyed by high temperatures. They contain azotobacters, phosphobacteria, des bactéries silicatées, lactic acid bacteria, des pseudomonas, actinomycetes, etc. They play different roles in the production of organic fertilizers. You can choose according to your needs.

When is it appropriate to add functional bacteria in the manufacture of organic fertilizers ?

What is the best step to add functional bacteria?

- When producing powdered biofertilizers, adding functional strains after composting is ideal.

- On the other hand, if you plan to produce granular biofertilizers, it is advisable to spray a microbial agent after granulation.

So, functional bacteria are protected from high temperatures. For the addition of microorganisms, we offer a double shaft mixer for manufacturing powdered biofertilizers and a coater for the production of quality biofertilizer granules. These two machines are equipped with a spraying device allowing precise addition of the bacterial agent.

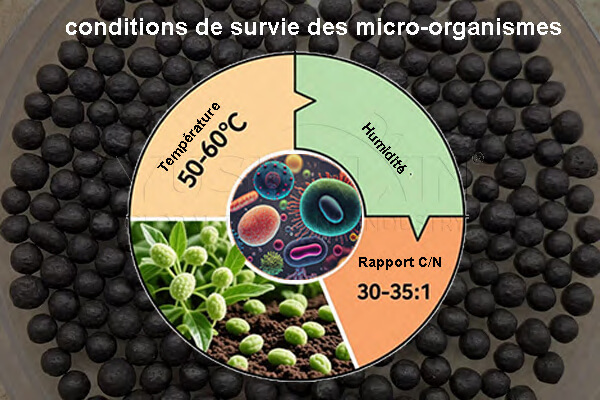

How to create an environment conducive to the life of functional bacteria?

To produce high quality biofertilizer, it is essential to ensure that the temperature is adjusted, moisture content, organic matter content and C/N ratio.

Temperature below 50°C

When the temperature reaches 60°C, 80 % microorganisms die. Therefore, after the addition of functional bacteria, the temperature of biofertilizers must be maintained below 50°C.

Moisture content

Moisture is essential for microbial activity. When manufacturing biofertilizers, it is therefore necessary to adjust it to an appropriate level, suitable for the manufacture of biofertilizer granules and conducive to the reproduction of microorganisms.

Rapport C/N

They also play an important role in the life of functional bacteria. For the manufacture of biofertilizers, it is preferable to control the organic matter content between 50 et 70 % and the C/N ratio between 30 et 35:1.

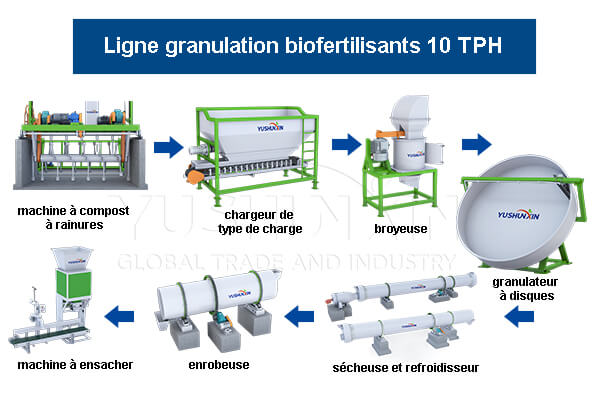

Top 2 biofertilizer production lines in YUSHUNXIN

In general, There are two types of organic biofertilizer production lines commonly used in biofertilizer manufacturing plants.

Powdered biofertilizer manufacturing facility

If you are looking for a simple and economical biofertilizer production system, our powdered biofertilizer production line is made for you. Composter, doser, crusher, mixer, screener and packaging equipment are at your disposal to produce quality biofertilizer from organic waste.

Organic fertilizer granule production line

To prepare a better quality organic fertilizer, screening is essential. A rotating powder screen separates waste and large particles from fine compost powder. Waste (stones, butts, etc.) are then discharged and the large particles are crushed. This improves the purity of the final fertilizer and reduces waste.

Can the lines produce biocompound fertilizers?

Of course. The organic powder and granular fertilizer production line can not only produce biocompound fertilizers, but also biocompound fertilizers. Simply use humus as a bacterial support, like peat, altered coal, lignite, etc.

What should be done for better composting of biofertilizers?

In general, composting plays an important role in the production of biofertilizers, because it eliminates harmful substances and bad odors from manure. SO, how to optimize the fermentation of biofertilizers? In addition to the addition of a microbial composting inoculant, the use of a professional composter is the ideal solution. It allows materials to be turned regularly to provide oxygen and dissipate excess heat. It promotes better aerobic fermentation of biofertilizers. Two compost turners are currently very popular with biofertilizer suppliers.

Wheeled composting machine for large-scale composting of organic fertilizers

If you want to purchase equipment for large-scale biofertilizer composting, we recommend our wheeled composter. Thanks to its rotation width of 10 has 30 m and its rotation depth of 1 has 2 m, it processes more organic matter than other composters in record time. What's more, to accelerate the fermentation of biofertilizers, we equipped it with an automatic electrical control system. So, without human intervention, it automatically moves along the rails on the sides of the fermentation groove to process the biofertilizer compost.

Windrow compost turner for small-scale fermentation of organic fertilizers

If you want to produce biofertilizing compost on a small scale, we also offer you a compost turner in windrows. It can handle compost piles with a width of 2,4 has 3 m and a height of 0,6 has 1,5 m. It can thus treat 500 at 1,500 m² of biofertilizer per hour. What's more, it is easy to use: even a skilled worker can easily compost large quantities of fertilizer windrows on level ground.

How to produce granular organic fertilizers?

To facilitate transport, storage and sale of organic fertilizers, most production plants prefer to transform them into pellets. For that, it is essential to purchase suitable pelletizing equipment. We recommend that you opt for the following two machines: a new type organic fertilizer granulator or a rotary drum granulator.

New type of granulator for small-scale granulation of organic fertilizers

If you are looking for a granulator for small-scale organic fertilizer processing, the new organic fertilizer granulator is the ideal choice. With a capacity of 1 has 8 t/h, it perfectly meets your small-scale production needs. What's more, thanks to the mechanical force of rotation of the stirring teeth, organic fertilizer compost is granulated. Final biofertilizer granules have higher hardness, which makes them more convenient to use.

Rotary drum granulator for large-scale pelletized biofertilizer production

For large-scale granulation of biofertilizers, we recommend a granulateur à tambour rotatif. It allows you to prepare up to 30 tonnes of biofertilizer pellets per hour. What's more, thanks to its rubber coating, its clean holes and lifting plates, it produces a biofertilizer with less adhesion. This results in an extended lifespan, less waste and better pellet production efficiency.

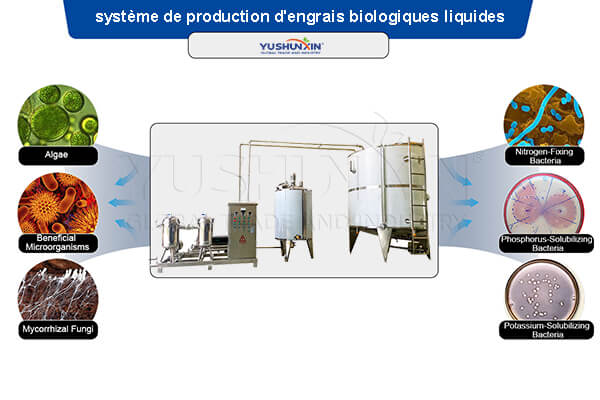

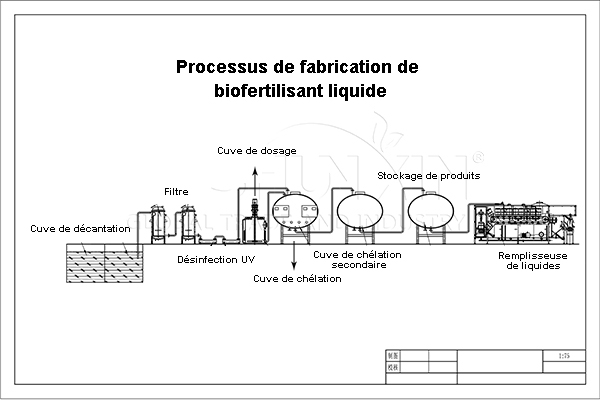

Is there a technology for producing liquid biofertilizers?

The answer is yes. We also offer machines suitable for the production of liquid biofertilizers, including manure dehydrators, activated carbon filters, UV disinfection systems, bacteria or NPK dosage tanks, fermentation tanks, etc. These machines are all made of stainless steel, a material resistant to liquid erosion. We can also produce liquid organic fertilizers from organic and chemical materials.

Are these solutions only intended for the preparation of organic biological fertilizers??

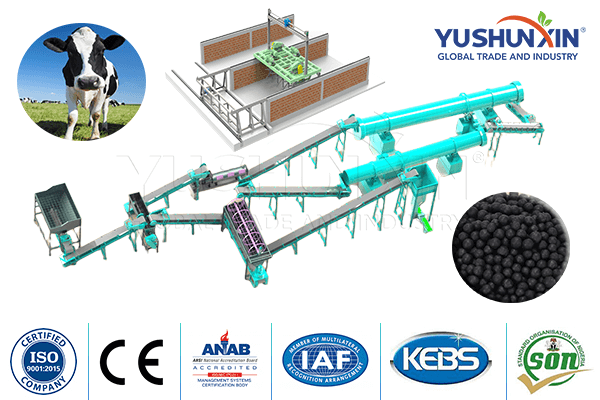

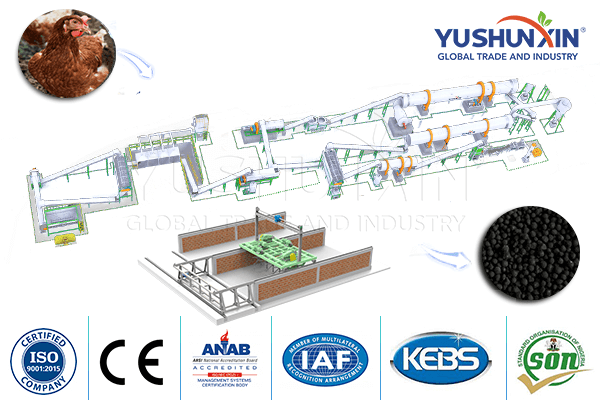

The main application of the above systems is the production of organic biological fertilizers. They mix beneficial microorganisms with organic waste compost or carrier materials, then turn them into powder, liquid or granules. They perfectly meet your needs production d’engrais à base de bouse de vache, processing chicken droppings into fertilizer, manufacturing of organic pig manure fertilizer, etc., with beneficial microorganisms.

If the manufacture of organic biological fertilizers is a preferred choice by manufacturers, The organic fertilizer production solutions described above can also be integrated into chemical fertilizer production processes, notably the NPK fertilizer production, the bulk fertilizer production, the manufacturing of natural phosphate fertilizers, etc. YUSHUUNXIN can offer you tailor-made compound organic fertilizer production solutions!

Where are your established biofertilizer production plants located? ?

During the 20 recent years, we have helped many fertilizer manufacturers to successfully start their organic fertilizer manufacturing plants. For example, We we manufacture organic fertilizers in Canada. To discover the biailled fertilizer production chain, please feel free to visit our factory in Xingyang, Zhengzhou, Henan province, in China. We also have subsidiaries abroad, especially in Indonesia, in Algeria, in Russia and the United States.

For any other request regarding the manufacture of organic fertilizers, do not hesitate to contact us immediately. We offer a tailor-made bacterial fertilizer production plan. YUSHUNXIN also offers many other fertilizer production plans, such as a biochar fertilizer production line, an NPK fertilizer production system, a organic fertilizer granulation line of 20,000 t/year, etc.