In Tunisia, a company operating 500 000 laying hens decided to transform chicken waste into value thanks to valorization of poultry manure. So, she is interested in the production of granulated organic fertilizers from chicken manure. Then, the 6 august 2024, she sent us an email regarding a chicken waste management plan for a chicken farm 500,000 poultry. The raw materials are chicken manure and palm leaves, with humidity of 70 %. For that, we sent him a chicken droppings granulation line from 5 tons per hour, with a sale price of 106,490 $. Here are the details of our communication regarding this case:

Project presentation

- Lieu : Tunisia

- Ability : 5 T/H

- Cost : 106 490 $

- Material : Chicken farming waste, palm leaves

- Need : Manufacture of fertilizer granules

- Solution : Disc granulation solution

What fertilizer manufacturing system capacity is needed for valorization of poultry manure from 500000 chickens ?

Each hen produces approximately 0,15 has 0,2 kg of manure per day, so for 500,000 birds, the daily quantity of fresh manure reaches approximately 75 has 100 tons. After humidity reduction by the dehydrator, the effective contribution becomes approximately 40 has 45 tons. What's more, with the mixture of palm leaves, a chicken manure granulation system 5 tons per hour is an ideal choice. With two work shifts per day and 8 hours per shift, it is possible to produce 70 has 80 tons of organic fertilizer granules. Therefore, a granulation line 5 TPH can perfectly meet your needs for large-scale chicken waste management in Tunisia.

Can we produce organic fertilizer from chicken manure on a budget of 100,000 $ ?

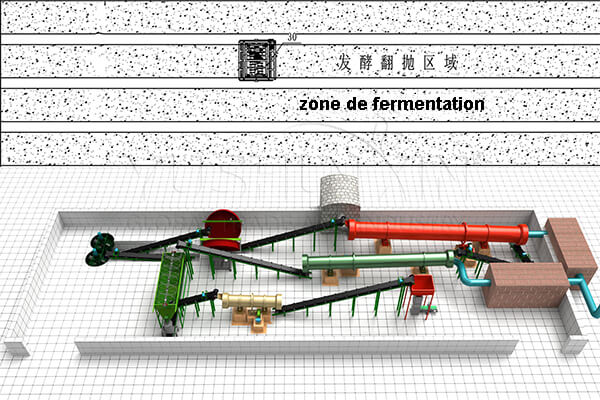

Ensuite, the Tunisian manufacturer hoped that the budget for the purchase of chicken manure fertilizer equipment could be controlled around 100,000 $. For that, we recommend purchasing several main machines to process chicken manure into granulated organic fertilizer. These include the dehydration screw, compost turner in trench, vertical crusher, du tray granulator, of the drying system, packaging machine and conveyors. Each piece of equipment has a specific role and a clear cost, as follows :

- SXTS-230 Dewatering Screw (4,560 $) : reduces humidity 70 % at around 30–40%.

- Trench compost turner SXCF-4000 (13,668 $) : ensures aerobic fermentation and odor control.

- SXFLF-800 vertical crusher (6,636 $) : breaks up clumps for uniform granulation.

- SXYZ-3600 Disc Granulator (14,503 $) : shapes fermented compost into uniform granules of 2 has 5 mm.

- Drying system SXHG-1616 (35,815 $) with gas burner and hot air oven (13,465 $) : eliminates excess humidity for better conservation.

- SXBZ-50 packaging machine (8,182 $) : automates bagging.

- 5–6 belt conveyors (10,768 $) : connect the whole process.

- PCL container (4,568$) : Controller for automatic chicken manure fertilizer manufacturing system

| Equipment | Model | Ability | Power (kW) | Prix (USD) |

|---|---|---|---|---|

| Dehydration screw | SXTS-230 | 15-20 m³/h | 4,560 | |

| Compost turner in trench | SXCF-4000 | 1500-2000 m³/h | 15*2 | 13,668 |

| Concasseur vertical | SXFLF-800 | 5-8 T/H | 30 | 6,636 |

| Disc granulator | SXYZ-3600 | 4-6 T/H | 18.5 | 14,503 |

| Drying system | SXHG-1616 | 6-8 T/H | 15 | 35,815 |

| gas burner and hot air oven | – | – | 11 | 13,465 |

| Packaging machine | SXBZ-50 | 20-50kg/bag | 3 | 8,182 |

| belt conveyors | B-600 | 5–6 sets | 20-24 | 10,768 |

| PCL container | – | – | – | 4,568 |

Adding up all the costs, the total investment for the purchase of a chicken droppings pellet machine is 112,095 $ EXW. What's more, thanks to the payment of a deposit of 50 %, a discount of 5 % is granted. The final quote EXW for organic fertilizer production line intended for a breeding of 500,000 poultry in Tunisia therefore amounts to 106,490 $.

Positive reviews from Tunisian poultry farmers on the disc fertilizer granulation line

After installation, the Tunisian farm reported excellent results. Poultry manure recovery line works smoothly, reduces odors in livestock and improves environmental conditions. At the same time, new organic fertilizers have created an additional source of income, because local farmers are looking for economical fertilizers. The farm estimates that with stable sales, the investment can be recovered in one year, while achieving both waste reduction and increased profits. This positive feedback shows that professional technology of producing fertilizer from chicken manure is not only feasible, but also a very profitable solution for large poultry farms in Tunisia.

The details above present our communication with the client regarding the valorization of poultry manure in a poultry farm. 500,000 poules en Tunisie. What's more, we also provide solutions for production d’engrais à partir de bouse de vache, of granulation SSP, of NPK fertilizer production plans, etc. Don’t hesitate to get your own fertilizer business plan now !