The 13 avril 2025, a Canadian customer contacted us with a clear request : he needed an azotobacter biofertilizer manufacturing system 10 t/h which is both profitable and efficient. This was to be used to treat biogas residues, chicken droppings, pig manure and other agricultural waste. Furthermore, the customer hoped to use heat from biogas production for drying biofertilizers and at the same time achieve high bacterial survival. Here are the specific details of our communication in this case :

Project Overview

- Localisation: Canada

- Ability: 10 t/h

- Materials: biogas residues, chicken droppings, pig manure and other agricultural waste

- Need: granulation de biofertilisant Azotobacter

- Solution: double disc granulation system

Can you suggest a simple process for manufacturing biofertilizer from 10 t/h ?

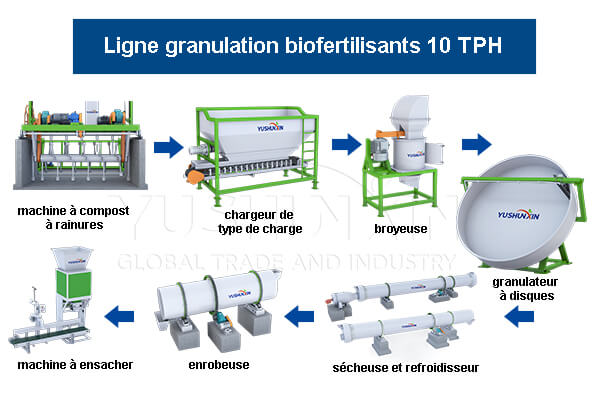

Ici, you can acquire a biofertilizer granulation line with only several key machines. For the manufacture of azotobacter biofertilizer 10 TPH, it is advisable to purchase a grooved compost turner SXCF-5000, a loading feeder, a vertical crusher SXFLF-1000, two SXYZ-3600 disc granulators, a rotary dryer SXHG-2020, a coating machine as well as a double bucket bagging machine.

- The grooved compost turner is used to mix and aerate raw materials, which guarantees correct aerobic fermentation of organic waste.

- Ensuite, the loading feeder transfers the materials to the vertical crusher which finely reduces them.

- These crushed materials are then transformed into pellets by the disc granulator, then they are dried in a rotary dryer to remove excess moisture.

- After drying, The granules are coated in a rotary coating machine and finally packaged with a double bucket bagging machine.

Why add azotobacter with coating machine after compost granulation ?

As the rotary drying process involves high temperatures (>60℃), direct addition of bacteria during granulation would greatly reduce their viability. More, it is different to add’azotobacter with a coating machine after drying. This is beneficial not only to improve the survival of bacteria in the manufacture of azotobacter biofertilizer, but also to guarantee a uniform coating.

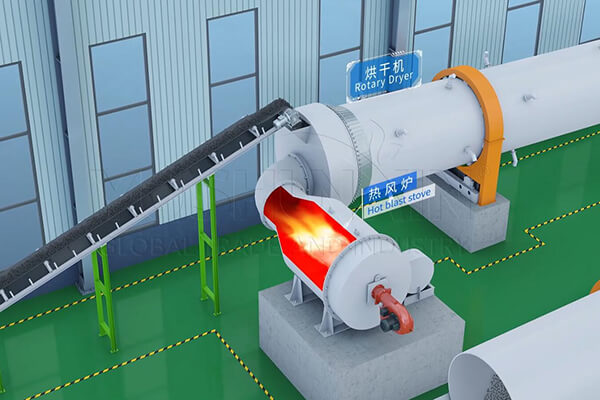

Can the heat of a biogas unit be used to dry biofertilizer granules? ?

What's more, for drying biofertilizers, the Canadian customer wanted to integrate the waste heat of a biogas unit. Is it possible ?The answer is yes. Ici, YUSHUNXIN will offer customized layout design of your azotobacter biofertilizer granulation plant according to your requirements.

However, we recommend that you also adopt alternative fuels for rotary drying, such as diesel, natural gas or biomass pellets. There are professional burners and hot air generators suitable for you. What's more, we also offer generators of 50 has 1000 kW to ensure a stable energy supply.

The above presents the details of our communication with the customer regarding azotobacter biofertilizer manufacturing of 10 t/h au Canada. Furthermore, we also offer you roller granulation lines secs, of the rotary drum granulation plans avec une capacité de 10 has 30 TPH, etc. Welcome to develop your own fertilizer business plan now !