The fertilizer blending plant is set up for produce compound fertilizers by uniformly mixing multiple chemical granules in specific proportions. This type of fertilizer is often called bulk fertilizer production, abbreviated as BB fertilizer (Bulk Blending). Usually, its nutrient proportion is not fixed and can be adjusted according to local agricultural conditions. This is why more and more fertilizer manufacturers prefer to invest in bulk fertilizer production. In this regard, YUSHUNXIN, en tant que fabricant professionnel d’équipements pour engrais, can provide proposals in several areas. This includes material selection, choosing the location of the factory, the choice of business plan, etc.

Settings

- Ability: 5-40 t/h

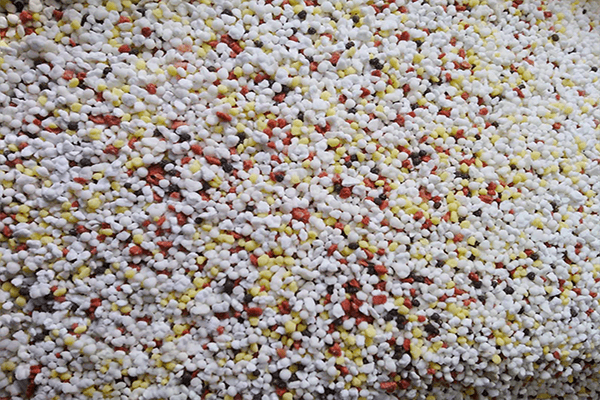

- Material: Chemical granules

- Conception: Crusher, BB fertilizer mixer, packaging equipment.

- Surface: 500-2 000 m²

- Cost: 20 000 $ – 220 000 $

- Applications: Urea, DAP, MOP, SOA, granular sulfur, phosphate naturel, etc.

How to Prepare Materials for Fertilizer Blending Plant Installation ?

When you want to start bulk fertilizer manufacturing, Preparing materials is an essential point you need to focus on. SO, what is the principle of material selection for BB fertilizer production ? In general, you should pay attention to three principles :

Chemical materials

Bulk fertilizer is a type of compound fertilizer. So, the raw materials used are generally simple chemical fertilizers or complex fertilizers, such as urea, the gypsum, dAP, with TSP, le sulfate d’ammonium, etc.

Uniform pellet size

In general, fertilizer blending plant is constructed to process granular chemical materials to produce the desired fertilizer. This is the premise for using chemical fertilizer granules to start making BB fertilizer.. What's more, to obtain high quality bulk fertilizer, it is advisable to choose pellets of uniform size. Otherwise, the nutrients in the fertilizer may overlap during transport, which would affect the supply of nutrients for crop growth.

Absence of chemical reaction

Finally, it is preferable to choose materials that do not cause any chemical reactions. Indeed, a chemical reaction is a process that leads to the chemical transformation of one set of chemical substances into another. This changes the nutrient proportion of the fertilizer and can even generate harmful substances.

What equipment is needed for bulk fertilizer production ?

In addition to the selection of suitable materials, it is also necessary to purchase professional equipment for the fertilizer mixing plant. This is crucial to ensure rapid and smooth production of bulk fertilizers. But what equipment is needed for the production of BB fertilizer ? In general, you will need the following four processing machines :

Dosing machine

As mentioned above, BB fertilizer is a mixture of various chemical materials in precise proportions. If the proportion is changed, the final fertilizer will no longer be adapted to local agricultural conditions and may even cause damage. But how to make sure to make the BB fertilizer strictly according to the proportion of the formula ? Using a dosing machine, equipped with an electric weighing system, allows the different chemical materials to be dosed precisely and in the required order, rather than feeding all materials at once.

BB Fertilizer Mixer

As its name suggests, mixing machine plays a key role in bulk fertilizer production. For this purpose, we designed a professional BB fertilizer mixer. The latter overcomes the mixture chromatography and distribution phenomena caused by different proportions of raw materials and particle size. What's more, it also resolves the influence of material properties, mechanical vibrations, air pressure, etc. So it can help you mix chemical materials evenly to ensure the nutrient balance of your BB fertilizer.

Automatic packaging machine

After mixing, you can directly package the compound fertilizer. What a simple process ! To accelerate the production of bulk fertilizers, we recommend purchasing an automatic packaging machine. It is equipped with an automatic weighing system which offers precision of 2 ‰. This allows you to quickly package BB fertilizer in bags of 10 kg, 25 kg, 50 kg, etc. So, you can carry them, store and sell them more easily.

Fertilizer conveyor

If you want to ensure smooth operation of bulk fertilizer production, you will also need to purchase a conveyor. This is used to transport chemical materials from one equipment to another. For that, we can provide you with belt conveyor, a moving belt conveyor, a bucket elevator, etc.

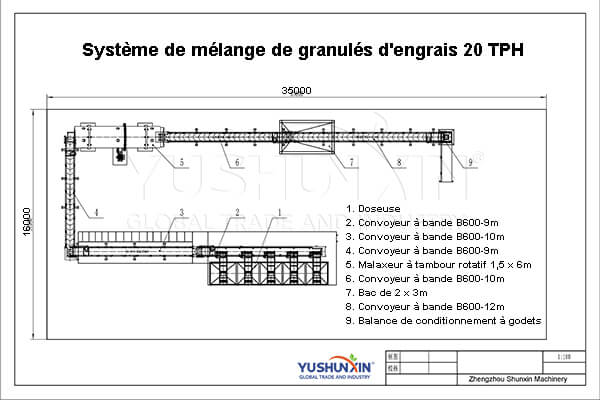

The two main business plans for BB fertilizer production

To meet the diverse needs of fertilizer suppliers, we have specially designed business plans for fertilizer blending with different capacities. One is for small compound fertilizer manufacturing plants, requiring the production of 5 has 10 tons of BB fertilizer per hour. The other is a rotating drum fertilizer mixing line, suitable for large-scale bulk fertilizer production.

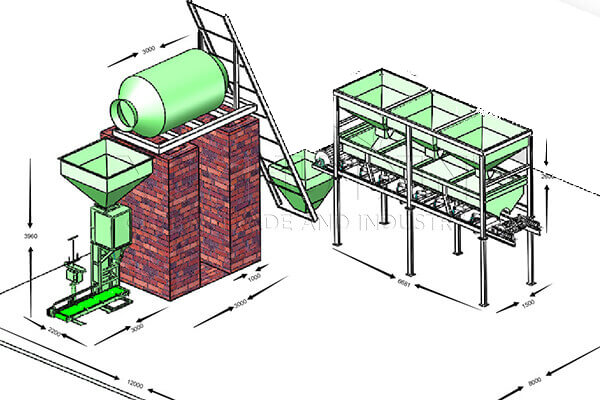

Small Scale Fertilizer Mixing Plan Design

When you need a BB fertilizer manufacturing line with capacity of 5 has 10 t/h, we recommend you choose our small scale fertilizer mixing system. It consists of a static dosing machine, of a wide angle belt elevator, a BB fertilizer mixer, and a single bucket bag packaging machine. This system operates on a positive rotation supply and reverse rotation discharge mode, which makes it easy to use. Furthermore, thanks to an internal spiral mechanism and a unique three-dimensional structure, it can mix materials evenly and export fertilizer without blocking.

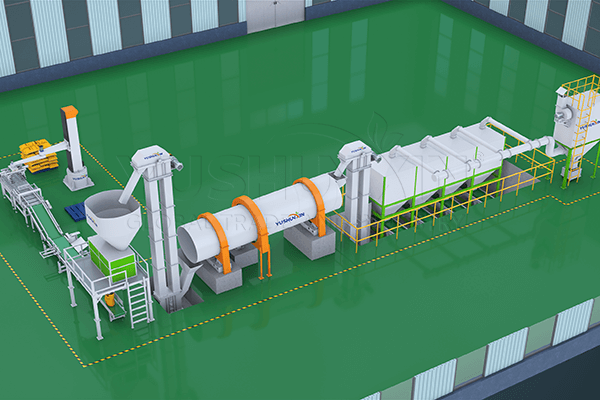

Large-scale fertilizer manufacturing line with rotating drum

If you want to set up a large-scale fertilizer blending plant, you can choose our rotary drum fertilizer mixing line. This line replaces the BB fertilizer mixer with a rotary drum mixer, offering a greater production capacity of 30 has 40 t/h. This means that it can help you produce between 180 000 et 250 000 tonnes of bulk fertilizer per year. Accordingly, it is recommended to change from single bucket packaging machine to automatic two bucket packaging system. This will allow you to quickly complete the manufacture of fertilizers in large quantities.

How to choose a location for installing the fertilizer blending plant ?

After collecting materials and purchasing equipment, you also need to prepare a suitable place for installing the fertilizer mixing plant. In general, there are two points to consider :

- Emplacement : It is best to start the preparation of BB fertilizer near the origin of the raw materials. What's more, it is advisable to build the fertilizer plant in places well served by transport. This will facilitate the transportation of materials to the factory and delivery of fertilizer products to customers..

- Surface : In general, a surface of 100 has 900 ㎡ is necessary. The bulk fertilizer manufacturing line can easily produce 5 has 80 t/h of chemical fertilizer.

Can Fertilizer Blending Plant Produce NPK Fertilizer ?

Of course. In reality, fertilizer mixing line is a compound fertilizer manufacturing process. There is therefore no doubt about its ability to be used in the NPK fertilizer production. Whether you want to produce NPK fertilizers 15-15-15, 20-10-10 or other types of NPK fertilizer, it can perfectly meet your needs. What's more, compared to NPK fertilizer granulation line, it offers greater flexibility for manufacturing NPK fertilizers with different proportions. Therefore, it is also wise to set up NPK fertilizer blending plant.

Furthermore, if you want to make other NPK compound fertilizers, we also offer different designs to meet your needs. This includes powder NPK fertilizer granulation line, the SSP phosphate fertilizer production plan and other fertilizer manufacturing projects based on mineral materials, etc. Do not hesitate to contact us to get these solutions now !