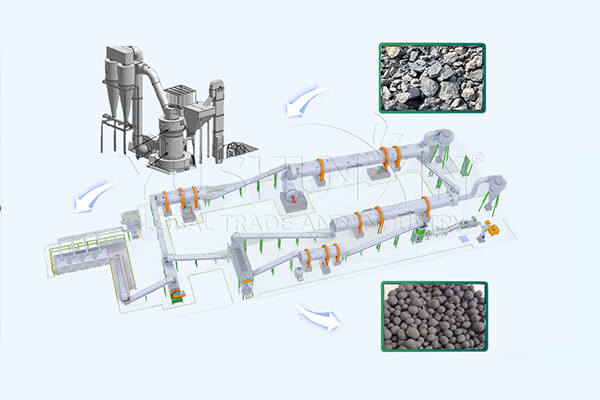

In the manufacturing of chemical fertilizers, SSP phosphate fertilizer production is favored by many fertilizer manufacturers. This is due to its richness in phosphorous elements., which play a crucial role in the germination and fruiting of plants. But how to make SSP phosphate fertilizer ? This process mainly uses SSP rocks and concentrated sulfuric acid/nitric acid as raw materials. Main stages include crushing, the mixture, l’acidification, aging, additional grinding, screening and packaging. Furthermore, you can choose to make it into SSP pellets. Finally, remember to filter residual gases to comply with local environmental requirements.

Settings

- Ability : 1 has 20 T/H

- Products : Powder or granules (1 has 10 mm)

- Cost : 100 000 $ has 600 000 $

- Equipment materials : Stainless steel, carbon steel Q235

- Applications : Phosphate, limestone, zeolite, bentonite, etc.

How to Process SSP Rocks for Phosphate Fertilizer Production ?

The main materials for the production of SSP phosphate fertilizers are phosphate rocks and concentrated sulfuric acid/nitric acid. However, it is not recommended to use them directly to prepare the required phosphate fertilizer. Several necessary processes must be carried out.

Crushing phosphate rocks into fine powder

For better manufacturing of SSP fertilizers, it is advisable to first crush the phosphate rocks into powder. On the one hand, SSP powder can mix completely with liquid acidic materials. On the other hand, powder material is very advantageous for making phosphate fertilizer granules. We recommend using a jaw crusher to break rocks into small particles. Ensuite, Raymond mill is an excellent choice for further grinding small SSP particles into a fine powder.

Mixture with sulfuric acid/nitric acid

In addition to phosphate rocks, l’concentrated sulfuric acid/Nitric acid is also an important material for making SSP phosphate fertilizers. Therefore, in order to produce quality phosphate fertilizer, it is necessary to mix SSP rock powder evenly with concentrated sulfuric acid/nitric acid. For that, we can provide you with the suitable fertilizer mixing equipment, whether small or large scale, with vertical disc mixers or various horizontal mixers.

Acidification and aging

Ensuite, you must transport the mixture of phosphate rock powder and acid in a closed room. In this room, the chemical reaction will take place fully, forming the necessary material. This process is called acidification and usually takes 3 has 4 hours. Is this the end ? Non. Due to the mixing of phosphate rock powder and liquid acid, Acidified SSP material contains moisture of 50 has 60 %, which does not meet the requirements for further processing. Therefore, you must age the SSP material + acid after acidification.

If you don't plan to make SSP pellets, just three steps : crushing, sieving and packaging. As a manufacturer of professional fertilizer manufacturing equipment, YUSHUNXIN can offer you an ideal plan for making powder SSP fertilizer.

What is the manufacturing process of SSP fertilizer granules ?

However, if you want to make SSP fertilizer pellets, after aging, you need to follow the following steps :

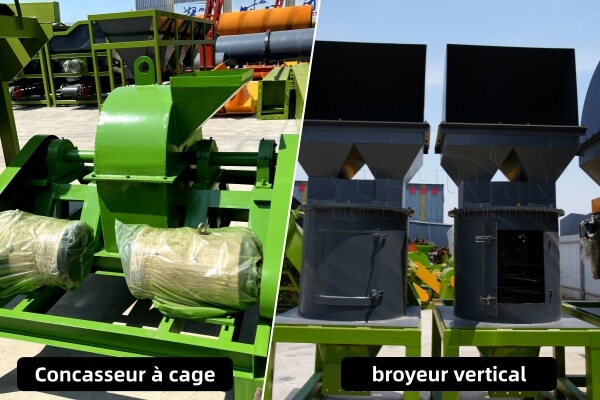

Grinding of aging material

Before you start manufacturing SSP fertilizer pellets, it is necessary to re-shred aging chemical materials. The particle size of the material is directly related to the granulation effect of chemical fertilizers. The finer the powder of the material, the easier it is to make SSP pellets, the better they look. But due to mixing of phosphate rock powder with concentrated sulfuric acid/nitric acid (liquid), aging SSP materials will contain many agglomerates. It is therefore necessary to transform them into fine powder with a suitable crusher..

Granulation SSP

Ensuite, you can move on to the most important step : granulation of SSP phosphate fertilizers. Here are three types of recommended NPK fertilizer granulators. If you are starting SSP fertilizer granulation on a small scale, it is advisable to purchase a disc granulator, whose capacity is 1 has 6 t/h. However, for large-scale SSP pellet manufacturing, the drum granulator is most suitable. It has a great capacity to 1 has 30 t/h, allowing you to efficiently produce chemical fertilizer pellets on a large scale. Is there a low cost phosphate fertilizer granulation plan? ? Of course. The double roller granulator is designed for you. It uses dry granulation method, allowing you to save on drying and cooling.

Screening

A quality criterion for the manufacture of fertilizer granules is uniform size. But there is no equipment with a granulation rate of 100 % for SSP pellets of the required size. SO, how to sift the necessary chemical granules, who can move on to the next step ? The rotary screen for pellets is here ! Galvanized steel mesh can divide phosphate fertilizer balls into small sizes, required sizes and large sizes. After screening, you can send the small and large size pellets back to crusher and pelletizing.

Drying and cooling

As mentioned above, dry granulation with a double roller granulator does not require additional drying and cooling. However, they are necessary for granulations of SSP materials with a disc or rotating drum granulator. The reason is that after wet granulation, the humidity of the fertilizer granules is approximately 20 %. It's not very high, but this is not sufficient for long-term storage. It is therefore necessary to add a dryer and a cooler after the disc granulator and drum granulator.

Packaging

In general, this is the end of the SSP phosphate fertilizer production line. Packaged fertilizer is more convenient for storage, transportation and use. For this step, YUSHUNXIN can also provide you with professional automatic packaging equipment, with a quantitative precision of 2 ‰. This machine can help you quickly pack the finished SSP fertilizer granules into bags.

How to eliminate residual gases generated by the production of SSP phosphate fertilizers ?

For the establishment of an SSP phosphate fertilizer manufacturing plant, there is one point you need to pay attention to : residual gas treatment.

To prevent environmental pollution, exhaust gas from phosphate fertilizer manufacturing is essential. But how to make exhaust gases harmless ? We recommend purchasing our water curtain dust collector. Under the action of water, the residual gases become hydrofluoric acid and hexafluorosilicic acid, which makes it possible to comply with international discharge standards.

Cases of phosphate fertilizer production in the world

During the 20 recent years, YUSHUNXIN has helped many SSP phosphate fertilizer manufacturers to start their business. They come from countries like Romania, Morocco, Colombia, Pakistan, Iran, Egypt, etc. Here are some examples for your reference. For example, the manufacture of granulated phosphate fertilizers 200 TPD in Morocco, etc.

Furthermore, in addition to the project to transform phosphate rocks into fertilizer, we can also offer you many other solutions for the manufacture of fertilizers from mineral waste. Like limestone fertilizer production line, the zeolite granulation plan, etc. Or you can also choose to use mineral waste in the NPK fertilizer production. Please feel free to contact us to get your own fertilizer business plan.