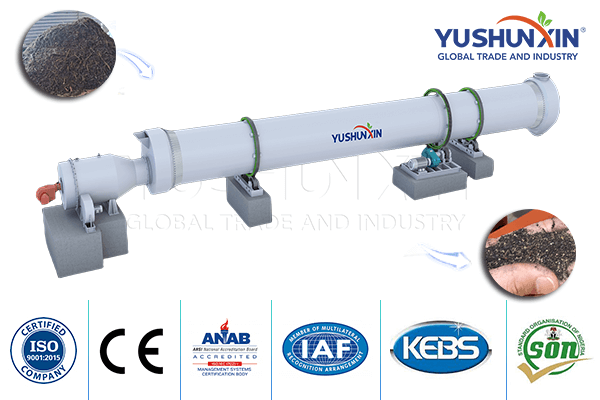

Rotary drum dryer is an essential equipment in fertilizer production, especially for wet granulation processes. It reduces the humidity of fertilizers up to 10 %, improves particle hardness for easier transportation and storage, while avoiding sticking and deterioration. To fully meet your fertilizer drying needs, there exists 3 types of dryers for you : chicken manure dryer, cow dung dryer and compound fertilizer dryer. They can dry powders and granules of 1 t/h to 20 t/h quickly, with a price varying only from 7 000 $ has 150 000 $.

Settings

- Ability : 1 at 20 t/h

- Final humidity : < 10 %

- Drying method : hot air drying

- Drying temperature : 300 °C

- Drying fuel : fuel oil, gaz, biomass pellets, firewood, etc.

- Cost: 10 000 $ at $130,000

- Application : Powders and granules, manure, NPK, sludge, etc.

What can a rotary dryer do for fertilizer manufacturing? ?

The rotary dryer plays a crucial role in your fertilizer manufacturing process, especially when you adopt wet granulation method. For what ? What benefits can this fertilizer drying machine bring you ?

Facilitate the transport of your finished fertilizers

In general, after wet granulation, the water content of your fertilizer granules is still 30 %. But using a rotary dryer, you can reduce this rate to 10 %. In this way, you get fertilizer granules with higher hardness, i.e. less risk of spraying and increased convenience for transport.

Extend the storage life of your fertilizers

YUSHUXNIXN fertilizer dosing equipment generally adopts electric weighing technology. It thus allows the different raw materials to be dosed according to the required proportions.. So, you can produce organic fertilizer richer in nutrients and better quality.

Top 3 fertilizer drying machines popular with manufacturers

From the introduction above, we know the importance of rotary drying equipment in fertilizer manufacturing. But there are many models of dryers on the market : which one is best suited to your needs ? Ici, to fully meet your requirements, YUSHUNXIN specially designed several models of dryers for your choice. The three best-selling are as follows :

Rotary dryer for chicken manure

When you consider transform chicken manure into organic fertilizer, high moisture content is a key point. This also applies to drying, because it considerably influences the efficiency of the process. That's why we specially improved our chicken manure drying equipment. The inlet temperature exceeds 300℃ and the contact temperature of materials can reach 70℃ – 80℃. So, it quickly reduces the moisture in your chicken manure fertilizer. What's more, après séchage, the water content of the pellets is only about 10 %.

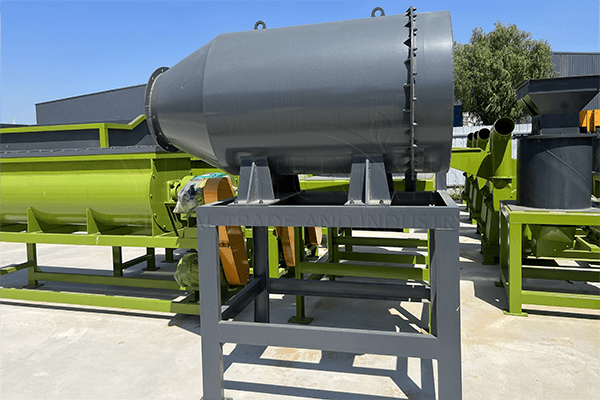

Cow Dung Drying Equipment

For those who wish make fertilizer from cow dung, we recommend our large capacity rotary dryer. Indeed, a cow generates on average 30 kg of manure per day, much more than a chicken. For that, SXHG-2020 rotary dryer and SXHG-2424 drum dryer are excellent choices. Their capacities are respectively 8-16 t / h and 14-18 t/h

Dryer for NPK compound fertilizers

In addition to the two types of dryers above, NPK compound fertilizer dryer is also highly appreciated by manufacturers. Because we equip it with internal lifting plates, which significantly reduces erosion caused by chemical materials and wet granulation. So, when using wet granulation method to produce NPK fertilizers, it is an ideal choice.

Details of rotary dryer technological parameters

| Model | Puissance moteur (kw) | Inlet temperature (°C) | Angle installation (°) | Vitesse (tr/min) | Ability (T/H) |

|---|---|---|---|---|---|

| SXHG-0808 | 5.5 | ≥300 | 3-5 | 6 | 1-2 |

| SXHG-1010 | 7.5 | ≥300 | 3-5 | 6 | 2-4 |

| SXHG-1212 | 7.5 | ≥300 | 3-5 | 6 | 3-5 |

| SXHG-1515 | 11 | ≥300 | 3-5 | 6 | 4-6 |

| SXHG-1616 | 15 | ≥300 | 3-5 | 6 | 6-8 |

| SXHG-1818 | 22 | ≥300 | 3-5 | 6 | 7-12 |

| SXHG-2020 | 37 | ≥300 | 3-5 | 5.8 | 8-15 |

| SXHG-2222 | 37 | ≥300 | 3-5 | 5.5 | 8-16 |

| SXHG-2424 | 45 | ≥300 | 3-5 | 5.2 | 14-18 |

How Rotary Drying Equipment Works to Dry Your Fertilizer ?

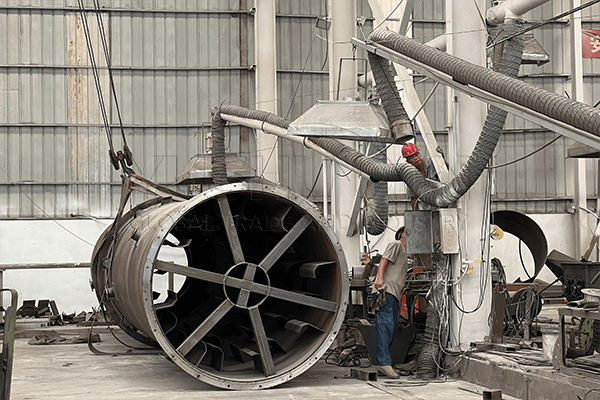

After purchasing a rotary drying machine, it is also necessary to understand its working process. It can help you start fertilizer drying more easily. In general, we can divide the drying process into three stages :

Supply of fertilizers

When the temperature at the bottom of the drying equipment reaches a suitable level, the belt conveyor or bucket elevator transports the fertilizer to the feed hopper. Ensuite, under the action of the rotation of the drum and gravity, the fertilizer disperses evenly in the dryer and rolls continuously.

Hot air injection to dry the fertilizer

Ensuite, hot air is injected into the dryer in order to come into contact with the materials used to make organic fertilizer or NPK. It then transfers heat to the material by conduction, convection and radiation. Therefore, the temperature of the material increases continuously and the moisture gradually evaporates.

Unloading finished fertilizer

Finally, fertilizer products that reach the required humidity level are discharged through the outlet. While non-compliant fertilizers remain in the equipment for further drying. But besides that, some residual gases are generated. How to treat these gases ? For that, we can provide you with professional dust collectors.

Is the drying machine suitable for powder or granular fertilizer ?

Our rotary dryer has wide application. Whether you want to dry compost powder or fertilizer granules, organic fertilizer or compound fertilizer, it can fully meet your needs.

What other equipment is needed when drying fertilizers ?

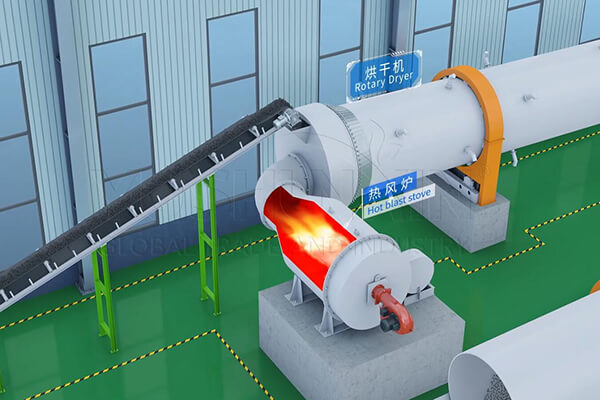

Natural gas burner

Natural gas burner is one of the main gas combustion equipment. In the fertilizer manufacturing process, it constitutes the heat source for drying. Can it be used for other raw materials ? Of course. What's more, we can also provide you mixed combustion machine (oil and gas). So it is an ideal new energy heat source for national environmental protection.

Hot air oven

But if you want to transport the hot air to the rotary drying machine, a hot air oven is also necessary. This machine is mainly used to store hot air. Then, with the help of fans, it transports hot air to the fertilizer drying equipment. Can it withstand the heat of drying? ? The answer is yes. We specially equip it with plates in manganese steel outside and refractory bricks inside. What's more, we can offer you different models according to your needs.

Fertilizer Cooling Machine

After treatment by the rotary dryer, the temperature of the final fertilizer is between 30℃ and 40℃. This affects the quality of the fertilizer you prepare and makes it unsuitable for storage. It is therefore necessary to reduce the temperature of the fertilizer after drying. At that moment, the rotary cooling machine will be of great help to you.

How much does rotary drying machine cost ?

Finally, price is an aspect that most fertilizer manufacturers pay great attention to when purchasing a rotary drying machine.

However, it is not fixed and varies depending on production capacity. The lower the capacity, the higher the price. The greater the capacity, the lower the price. So, YUSHUNXIN, en tant que fabricant fiable d’équipements pour engrais, can provide you with a quality dryer at a favorable price. The cost varies between 7 000 et 150 000 $. If you would like to obtain a detailed quote, please contact us immediately via the form below.

What's more, there are also compost machines, fertilizer granulator, granule coater, packing scale, etc, for your waste recycling project and the establishment of your fertilizer manufacturing plant. Come and discover them now !