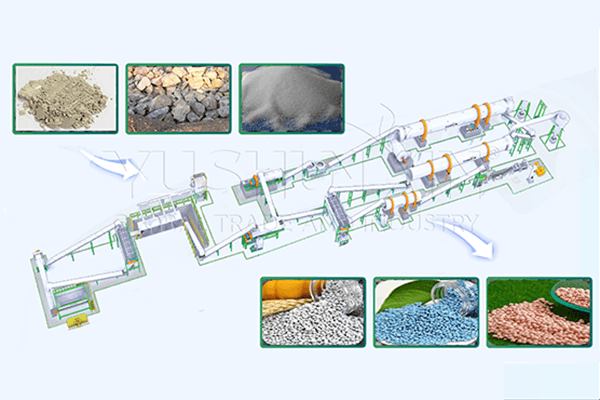

In general, when you need an NPK fertilizer production plan, there are two methods popular with NPK fertilizer manufacturers. This is NPK fertilizer granulation line and NPK fertilizer mixing system. The first allows you to transform powdered chemical fertilizers into NPK fertilizer granules.. The second can turn granular chemical fertilizers into the NPK fertilizer you need. You can choose one or the other depending on your raw materials, your budget, your factory space, etc. If you have specific needs, you can contact us immediately for solutions. YUSHUNXIN can provide you with a customized design plan for your NPK fertilizer plant.

Settings

- Ability: 1 at 20 t/h

- Type: Pellets/Mixture

- Cost: 30 000 $ at $500,000

- Equipment material : Q235 Carbon Steel/Alloy

- Application: Urea, MOP, SOP, KCL, etc., for NPK fertilizer

how to choose materials for your NPK fertilizer manufacturing?

For the preparation of NPK fertilizers, the first step is the choice of materials. For that, you need to focus on two points when selecting raw materials for the production of NPK fertilizers.

Types of materials for making NPK fertilizers

Manufacturing of NPK fertilizers, as its name suggests, consists of preparing a fertilizer containing elements rich in nitrogen, phosphorus and potassium. SO, what materials can provide these elements in your fertilizer manufacturing process ?

- Nitrogen materials for NPK fertilizer: If you want to make a nitrogen-rich NPK fertilizer, you can use urea, ammonium chloride, of ammonium sulfate, du nitrate d’ammonium, you nitrates of calcium, etc.

- Phosphate materials for NPK fertilizers: To increase the phosphorus content of your NPK fertilizer, monoammonium phosphate (MAP), diammonium phosphate (DAP), le superphosphate triple (TSP) and the superphosphate (SSP) are great options.

- Potassium materials for NPK fertilizer: For potassium intake, you can start your NPK fertilizer making plan with potassium chloride (MOP), potassium sulfate (SOP), potassium carbonate and plant ashes, etc.

NPK fertilizer preparation materials shapes

YUSHUXNIXN fertilizer dosing equipment generally adopts electric weighing technology. It thus allows the different raw materials to be dosed according to the required proportions.. So, you can produce more nutrient-rich and higher quality organic fertilizer.

What is the process of producing NPK fertilizer granules from powder ?

To maximize your profits, preparing NPK fertilizer pellets is an ideal choice. But how to quickly transform powdered chemical materials into commercial pellets ? Generally, it requires seven steps : weighing of materials, crushing, mélange, granulation, drying, cooling and bagging.

Proportional weighing of NPK materials

If you want to produce NPK fertilizer 20-20-20 or 20-10-10, how to adjust the proportions of N, P, K according to your formula ? Our dynamic weigher equips each hopper with an electronic belt scale. This allows materials to be fed precisely to make the required NPK fertilizer.

Crushing NPK into fine powder

To efficiently granulate NPK powder, it is recommended to use a fine chemical powder – 50-100 mesh. So, a suitable crusher is essential for manufacturing your NPK compound fertilizer. Vertical crusher and cage crusher are excellent choices. The first has a great capacity to 1 has 15 t/h and does not block. The second is more economical.

Homogeneous mixing of NPK powder

Ensuite, to guarantee a balanced distribution of nutrients in your pellets, it is necessary to mix the powders evenly, P and K before granulation. The horizontal double shaft mixer is ideal, and operates continuously without human intervention.

NPK fertilizer granulator

Granulation equipment plays an important role in the preparation of NPK granules. It transforms chemical powders into granules. Pour le fertilizer granulator, we offer granulator disc, rotary drum and double roller granulator. They fully meet the needs of manufacturing NPK fertilizer granules with 1-30 t / h and 1-10 mm.

Rotary pellet screener

After granulation, to guarantee the quality of the pellets, it is recommended to sift them with a rotary sieve, which separates NPK granules of the required size from others. You can then transport the qualified pellets to the next stage.

Concasseur à chaîne

How to deal with non-compliant pellets ? Throwing them away would be a waste ! You can re-crush them into powder and reintroduce them into the process.

Dryer and cooler

If you use the double roller granulator, there is no need to buy a dryer and cooler. However, for granulation with disc or drum, it is advisable to use them to eliminate excessive humidity.

Packaging equipment

How to deal with non-compliant pellets ? Throwing them away would be a waste ! You can re-crush them into powder and reintroduce them into the process.

Trick : The design of an NPK powder granulation line is fixed. For example, if you choose a double roller system, granulation is done by physical extrusion and not by liquid cohesion. Dryer and cooler are not necessary. What's more, if you want to change the final color or add a slow release film, coating machine is available before packing.

Is there a plan for making blended NPK fertilizer ?

If you are looking for an economical plan, you can opt for a NPK fertilizer mixing line. It uses granular fertilizers as raw materials.

Proportional material feeding

To produce the desired NPK fertilizer, it is essential to respect the proportions. The static weigher is highly automated and allows precise dosing, reducing time and costs.

Homogeneous mixture of NPK granules

Mixing is crucial for this line. BB mixer fixes issues with different proportions and sizes, guaranteeing uniform and easy mixing.

Final packaging of NPK fertilizers

After mixing, you can directly package NPK fertilizers and sell them.

Which NPK Fertilizer Manufacturing Business Plan is Right for You ?

Do you know which NPK fertilizer manufacturing plan is best for you? ? Ici, you can consider it according to the 4 following points :

Do you make NPK fertilizer from powder or granules? ?

When using powder or a mixture of powder and granular chemical materials, we recommend you choose NPK fertilizer granulation line. However, when dealing with complex granular materials, it is advisable to set up a mixed NPK fertilizer manufacturing plant.

How much budget do you plan for NPK fertilizer plant ?

For those who have sufficient budget for the manufacture of NPK fertilizers – of 100 000$ has 400 000$ – our NPK fertilizer granulation system is the optimal option. On the other hand, if you need NPK fertilizer plant plan for low cost production (20 000$ has 100 000$), you can opt for NPK fertilizer mixing line.

Do you want to produce NPK fertilizer on a small or large scale? ?

These two NPK fertilizer production plans can be used not only for small scale manufacturing, but also for large-scale production. However, there are also some differences between them. The maximum capacity of the NPK fertilizer granulation line is 30 t/h. While the large-scale NPK fertilizer mixing system can process 20 has 40 tons of NPK fertilizer per hour.

What area do you prepare for establishing NPK fertilizer factory?

If you have a workshop of more than 1 500 ㎡ for the preparation of NPK fertilizer, NPK fertilizer granulation line is your best choice. What's more, to start manufacturing NPK fertilizer in a smaller space of 500 has 1 500 ㎡, we can also offer you NPK fertilizer mixing system.

Besides the NPK fertilizer manufacturing plan, there are many other solutions for the production of compound fertilizers, such as the production of SSP phosphate fertilizer, project design to transform limestone into fertilizer, bentonite granulation plan, etc. Do not hesitate to contact us to get your own business plan for fertilizer manufacturing.