Are you looking for a granulator for large-scale fertilizer production? ? Do you want to prepare fertilizer granules in large quantities with low energy consumption? ? The rotary drum granulator can fully meet your requirements. It adopts wet granulation method, which uses a liquid as a binder to reinforce the cohesive force between the materials and thus transform the fertilizer powder into granules. In this way, it helps you produce quality fertilizer. What's more, to make fertilizer pellets more easily, YUSHUNXIN We have specially improved its internal design to reduce the possibility of adhesion to walls and increase granulation efficiency. Therefore, it can be used not only for the manufacture of compound fertilizers, but also for the production of organic fertilizers. Better yet, by combining it with other fertilizer machines, it allows you to set up a complete fertilizer granulation line and thus generate more profits !

Main parameters

- Ability: 1 has 30 t/h

- Particle size: 3 has 6 mm

- Granulation rate: greater than 90%

- Material humidity: 20 at 40%

- Particle size: 50 meshes

- Equipment material: Q235 carbon steel, rubber coating

- Applications: Manure, biogas residues, humus, NPK, bentonite, mineral waste, etc.

What Rotary Drum Granulator Can Do for Your Fertilizer Pellet Production ?

Drum granulator is widely used in the manufacture of granulated fertilizers, particularly in the industrial granulation of NPK fertilizer. For what ? What can it do for your pellet production? ?

Quickly complete large-scale fertilizer granulation

How to process chemical powder into pellets on a large scale ? Using a rotary drum granulator is an ideal choice.

In addition to models for small production, we also design different types of drum granulators for mass production of granulated compound fertilizers.

- For example, if you want to produce 8 has 15 tons of pellets per hour, we can provide you with model SXZG-2080.

- What's more, for even greater production, you can opt for the SXZGZ-3210, whose capacity reaches 15 has 30 t/h.

Technological parameters of rotary drum granulator

| Model | Power (kw) | Diameter (mm) | Length (mm) | Angle d’installation | Rotation speed (tr/min) | ability (T/H) |

|---|---|---|---|---|---|---|

| SXZGZ-1240 | 5.5 | 1200 | 4000 | 2-5° | 17 | 1-3 |

| SXZGZ-1560 | 11 | 1500 | 6000 | 2-5° | 17.5 | 3-5 |

| SXZGZ-1870 | 15 | 1800 | 7000 | 2-5° | 11.5 | 5-8 |

| SXZGZ-2080 | 18.5 | 2000 | 8000 | 2-5° | 11 | 8-15 |

| SXZGZ-3210 | 37 | 3200 | 10000 | 2-5° | 9.5 | 15-30 |

Produce NPK granules for you 3 has 6 mm

Can the drum granulator produce particles with the diameter you need ? Of course. In general, this granulating machine can process chemical powder into granules of 3 has 6 mm, size commonly used in agriculture.

SO, how to regulate the size of fertilizer granules during drum granulation ? Adjust the moisture content or control the drum rotation speed.

- The higher the humidity, the bigger the size ; plus l’humidité est faible, the smaller the size.

- The higher the rotation speed, the smaller the size ; the lower the rotation speed, the bigger the size.

Advice : During granulation, the water content must be maintained between 20 % et 40 %. This is the optimal humidity level for the manufacture of fertilizer granules.

Reduce your energy consumption in fertilizer manufacturing

What about the energy consumption of rotary drum granulator ? There is no doubt that this is a low energy consumption pelletizing machine. The power of our largest drum granulator, whose yield reached 15-30 t/h, is only 37 kw.

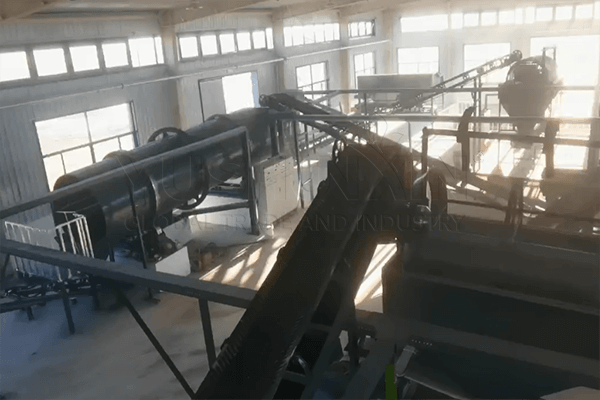

How the rotary drum granulator works to turn your fertilizer powder into pellets ?

As mentioned above, Rotary drum granulator uses wet granulation method to process fertilizer powder into pellets.

During the process, it exploits the cohesion created by the liquid in order to cause the powder particles to combine with each other and form granules in 3 has 5 minutes. What's more, thanks to the main motor drive, the large gear turns the drum, which also promotes the production of fertilizer granules.

How to Granulate Fertilizer Powder More Efficiently with Drum Granulating Equipment?

If you want to prepare better quality fertilizer pellets, you can inject steam into the rotating drum granulator. On the one hand, this moistens the powder, creating a sticky surface that allows particles to clump together into granules. On the other hand, this increases the temperature inside the drum granulator, which promotes rapid solidification and binding of the granules.

Thanks to this process, whether you want to launch cold or hot granulation production, or you are considering making fertilizer particles with high, medium or low concentration, rotary drum granulator can satisfy your needs.

3 Drum granulator designs to facilitate large-scale granulated fertilizer production

In the process of large-scale fertilizer granulation, there is one thing that most fertilizer manufacturers focus on. Due to wet granulation, materials tend to stick to the wall. This affects the granulation efficiency of granular fertilizer production with a rotating drum and causes serious erosion of the granulator.. For this reason, we specially improved the designs as follows :

Rubber coating

In order to enable the granulation equipment to resist the erosion of large-scale compound fertilizer processing, the best solution is to improve corrosion resistance. Based on using Q235B boiler steel to make the rotary drum granulator, we equip it with a coating in rubber. So, This granulation equipment has better resistance to erosion and a longer service life.

Stainless steel pressure bands

To improve the corrosion resistance of rotary drum granulation equipment, we adopt stainless steel pressure strips on the rubber coating. They firmly attach the liner to the inner wall of the granulating machine and have high erosion resistance thanks to the use of stainless steel as material.

Cleaning holes

But after a long time of operation, some materials still stick to the inner wall. And the granulation efficiency will be affected. SO, how to deal with these sticky materials ? You can eliminate them through special holes. By hitting these cleaning holes with a hammer, materials fall under the effect of vibration.

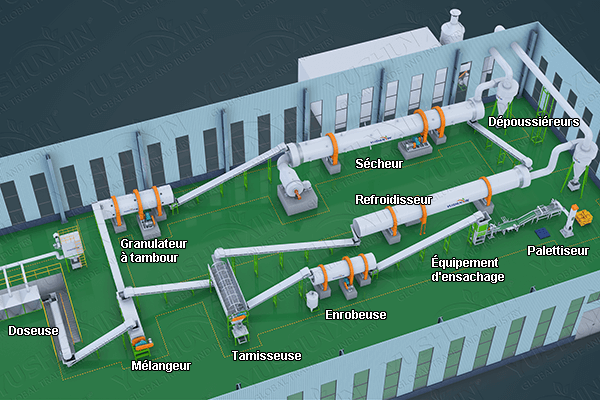

How to set up a drum fertilizer granulation plant ?

If you want to set up a rotary drum pelletizing plant, buying only the granulator is not enough. It is necessary to choose other fertilizer processing machines to establish a professional granulation line. In this process, cost and factory area are two things you need to pay attention to. So, to establish a drum fertilizer granulation plant, you need to perform the following actions :

What equipment is needed in a drum fertilizer granulation line ?

When you plan to create a compound fertilizer granulation line, in addition to the rotating drum granulator, you also need to buy a dosing machine, a crusher, a mixer, a screener, a dryer, a cooler, a dust collector, a dust chamber, coating equipment and belt conveyor. For organic fertilizer granulation line, you will also need a fertilizer dehydrator and a large composting machine.

What is the cost of setting up a drum fertilizer granulation plant ?

Cost also plays an important role in setting up a rotary drum pelletizing plant. It includes the cost of equipment, of the construction of the workshop, of energy consumption, employment of workers, etc. This cost is closely linked to the capacity. For a production of 1 has 30 t/h, you must plan a budget of 90 000 $ has 500 000 $ for a complete granulation line. Mais chez YUSHUNXIN, the original manufacturing plant, you can buy fertilizer equipment at a favorable price.

How much area does a drum fertilizer pellet making system occupy? ?

The area required also varies depending on capacity and configuration. In general, a drum granulation line 5 t/h requires a surface area of 3 000 has 4 500 ㎡. And you must plan a site 5 500 has 10 000 ㎡ for the installation of a drum granulation system 20 t/h.

For any questions regarding rotary drum granulators for fertilizer production or to get a customized fertilizer production plan, n’hésitez pas à nous contacter ! We also offer economical disc granulation equipment, of the double roller granulators for dry powder, new generation organic fertilizer granulators for the production of hard fertilizers, etc.