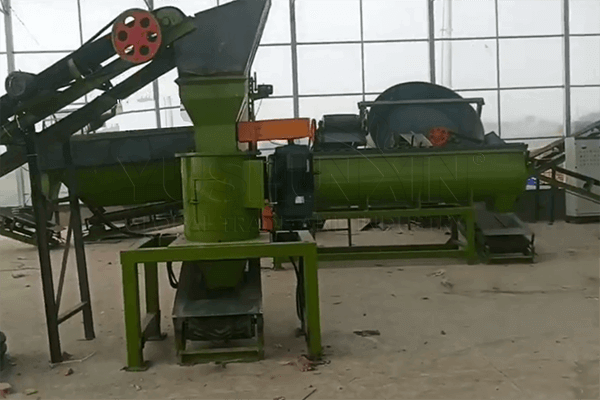

Tray granulator is one of the most popular fertilizer granulators which has won the trust of fertilizer suppliers, both in China and abroad, chez YUSHUNXIN. It features a simple design and easy operation. Whether you want to process chicken manure, cow manure or NPK materials into fertilizer granules, the disc granulator can accomplish it quickly. What's more, this equipment requires a low investment and a small installation area. So, if you want to start your fertilizer manufacturing business, it is an ideal choice for you.

Settings

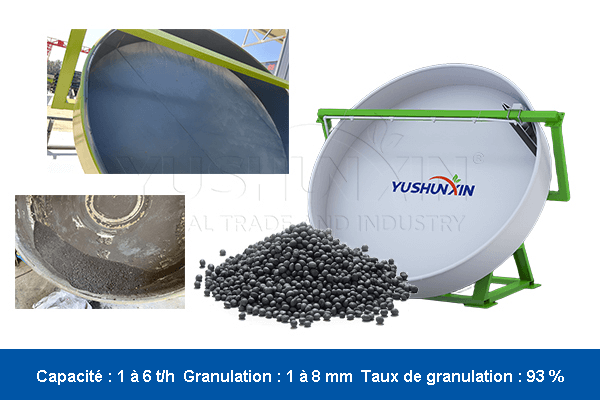

- Ability: 1 at 6 t/h

- Particle size: 1 to 8 mm

- Granulation rate: more than 93%

- Material humidity: 20 at 40%

- Particle size: 50 meshes

- Equipment material: Q235 carbon steel, alloy

- Applications: Manure, biogas residues, humus, NPK, bentonite, mineral waste, etc.

Why do many fertilizer suppliers use the tray granulator ?

Data shows that many fertilizer manufacturers choose disc granulator for their production lines. Here are the three main reasons :

Ability to 0,5 has 6 T/H

To fully meet the requirements of fertilizer suppliers, we design disc granulators of different capacities. So, if you need a small laboratory fertilizer granulator, we offer you the SXYZ 1500, with a minimum capacity of 0,5 t/h. For the disposal of animal waste on your farm, we offer the SXYZ disc granulator 3600, with a capacity of up to 6 t/h.

Granulation rate greater than 93 %

Our disc granulator has a high granulation rate of more than 93 %. This means it can produce more fertilizer pellets with the same amount of raw materials. This allows you to quickly transform fertilizer powder into granules and reduce material losses..

Attractive price between 3 000 et 16 000 USD

The advantageous price is also a major advantage for fertilizer producers who wish to acquire a tray granulator. In general, a disc granulator costs between $3,000 and $16,000. Why is this price so advantageous?? On the one hand, it is compact and offers a capacity of 0,5 has 6 t/h. The lower the capacity, the lower the price. On the other hand, YUSHUNXIN is a source factory for manufacturing fertilizer equipment. No additional fees are therefore applied during the transaction.

Technology Parameters of YUHSUNXIN Tray Granulator

| Model | Diameter (mm) | Edge Height (mm) | Rotation speed (tr/min) | Engine power (kW) | Ability (t/h) | Dimensions (mm) |

|---|---|---|---|---|---|---|

| SXYZ-1800 | 1800 | 300 | 21 | 3 | 0.8-1.2 | 2060*1700*2130 |

| SXYZ-2000 | 2000 | 350 | 21 | 4 | 1.2-1.5 | 2260*1650*2250 |

| SXYZ-2500 | 2500 | 450 | 14 | 7.5 | 1.5-2.0 | 2900*2000*2750 |

| SXYZ-2800 | 2800 | 450 | 14 | 11 | 2.0-3.0 | 3200*2200*3000 |

| SXYZ-3000 | 3000 | 450 | 14 | 11 | 2.0-4.0 | 3400*2400*3100 |

| SXYZ-3600 | 3600 | 450 | 13 | 18.5 | 4.0-6.0 | 4100*2900*3800 |

What materials can the tray granulator process into fertilizer granules ?

In general, collecting raw materials is the first step in fertilizer production. At the same time, the nature of the material plays an important role in the choice of granulator. Is this equipment suitable for your type of material ? The disc granulating machine is highly adaptable, which allows it to granulate various types of fertilizer materials, such as chicken manure, cow manure or NPK materials.

Chicken manure granulation

Are you looking for an effective way to recycle manure from your chicken farm ? Turning it into organic fertilizer pellets is an excellent choice. But if there is only limited space on the farm, how to do it ? The tray granulator perfectly meets these needs. It is a vertical granulation machine, which only requires 3 has 15 m² to complete the whole chicken manure granulation process.

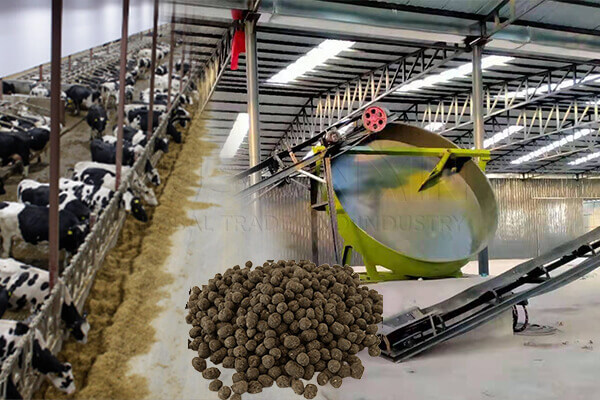

Manufacturing fertilizer pellets from cow manure

When you consider prepare fertilizer pellets from cow manure, you will notice that this material is corrosive. Can the disc pelletizing machine bear this corrosion ? Of course. The steel used for our pan pelletizing equipment is Q235B, a boiler steel recognized for its high resistance to corrosion. It therefore makes it possible to sustainably produce fertilizer granules based on cow manure.

Production of NPK fertilizer pellets

Is this type of granulating machine suitable for production of NPK compound fertilizer granules ? The answer is yes. Disc granulator can process different chemical materials N, P and K in high quality compound fertilizer granules. So, l’engrais NPK can be stored longer and provide targeted nutrients to crops.

Furthermore, you can also use the tray granulator to make pellets from limestone, phosphate rocks, bentonite, etc. It is suitable for almost all powder-to-granule processing processes.. If you have doubts, n’hésitez pas à nous consulter. What's more, we offer a granulation testing service, which allows you to check the performance of the process.

How the disc granulator works to transform fertilizer powder into granules ?

Once you have determined that the tray granulator is suitable for your raw materials, it is essential to understand how it works. In general, The disc granulation process is divided into five stages.

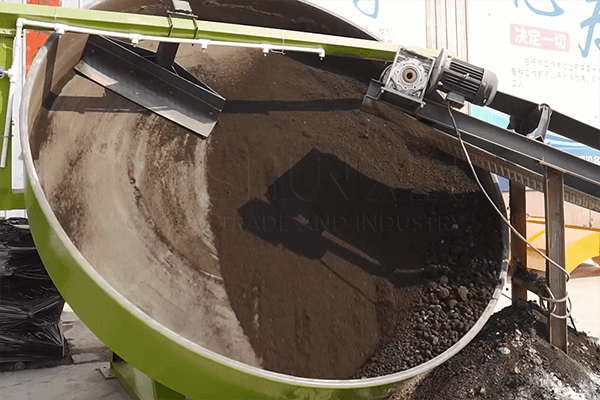

Tray Granulator Feed

At the power inlet, a belt conveyor continuously transports raw materials to the disc granulation equipment at a constant speed. To obtain better quality fertilizer granules, it is advisable to grind the materials into a fine powder, ideally from 50 mesh.

Disc angle adjustment

According to local needs, you may have to produce fertilizer pellets of different sizes. How to control them ? By adjusting the inclination of the disc : a steeper slope results in smaller pellets, a gentler slope results in larger pellets. The angle of the disc must remain between 40° and 60°, otherwise the powder will not turn into particles properly.

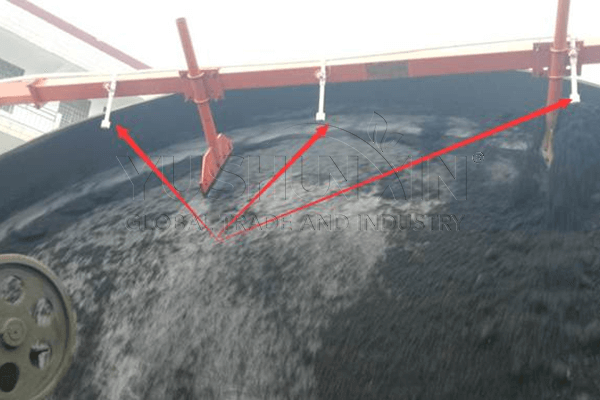

Spraying water to adjust humidity

Moisture content is essential for fertilizer granulation, just like for granulation in the tank. Disc granulator adopts wet granulation method, which uses liquid as a binder to facilitate the granulation of powder fertilizers. Therefore, controlling the water content of materials allows you to regulate the size of fertilizer granules: less water, smaller size; lots of water, bigger size. What's more, to facilitate control of the volume of water added, we have equipped our tank granulator with a spraying system.

Advice: Before granulation, it is recommended that the material has approximately 30 % humidity, and after granulation, the pellets approximately 20 %. If you want to reduce it to less than 10 %, you can use rotary dryer after granulation.

Formation of fertilizer granules

Under the effect of centrifugal force and gravity, fertilizer powder rolls and turns into spherical granules in 5 has 8 minutes. By adjusting the disc angle and humidity level, you can produce organic pellets or make compound fertilizer with a diameter between 1 et 8 mm.

Automatic unloading

When the pellets reach the desired size, the disc granulator automatically evacuates them. This is not a batch process, but continues : non-compliant granules remain in the disc and mix with new materials.

Can we adopt a closed granulation disc to limit dust? ?

This is not recommended. If the granulation disc is completely closed, material feeding becomes difficult. To control dust during manufacturing, just cover the machine with a protective structure, iron or plastic.

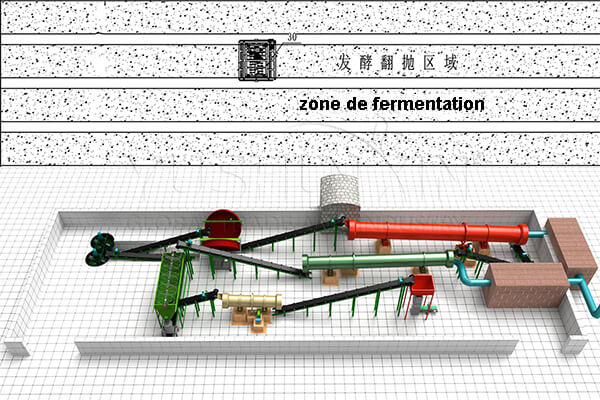

How to improve disc granulation system to produce better fertilizer ?

If you want to improve the quality of pellets, you can set up a complete disc granulation line.

Before the granulator, you can use a dehydration machine, un composter, a grinder and a mixer to prepare the materials. After granulation, you can add a sieve, un sécheur, a cooler, a coating machine and a packaging scale to improve product purity

If you are unsure about the configuration, tell us your conditions : type of material, budget, superficie, desired capacity and necessary equipment. We will design a customized granulation line according to your needs.

Are there any recent projects of manufacturing reference fertilizer for tray granulation machine?

Of course. In recent years, many fertilizer manufacturers purchase our disc granulation line for industrial fertilizer plant installation. Such as, valorization of poultry manure 500000 poulets en tunisie, 10 tph manufacturing of azotobacter biofertilizer in canada, production de granules engrais organiques 20000 t in senegal…

What's more, we also offer other types of granulators. High strength rotary granulator, double roller granulator without drying, or new type organic granulator. Contact us now for your own fertilizer pellet manufacturing plan.