Organic fertilizer fermenter is widely used in organic fertilizer composting. Indeed, it has high automation characteristics, shorter composting time, reduced pollution and limited space occupation. So, you can quickly and easily decompose organic matter and remove harmful substances. What's more, in order to meet different customer requirements, we specially design various closed tank fermentation reactors for your choice. Whether you are considering treating chicken manure, cow dung or pig droppings, to compost organic fertilizer on a small or large scale, they will definitely provide you with the best solutions. Furthermore, if you want to further transform the compost into organic fertilizer, YUSHUNXIN can also offer you plans adapted for your organic fertilizer project.

Main parameters

- Ability: 5 at 150 m³

- Composting method: In-vessel composting

- Composting duration: 10 at 15 days

- Occupied area: 10 to 30 m²

- Humidité des matières premières: 50 % at 60%

- Application: Poultry manure, bousier de vache, pig droppings, biogas waste, déchets de champignons, straw, rice husk, humus, etc.

Why organic fertilizer fermenter plays an important role in industrial composting ?

When you start composting organic fertilizer, what type of composting equipment do you want to buy ? Rapid composting ? Automatic ? Sans pollution ? Or low surface occupancy ? YUSHUNXIN closed tank composting equipment can perfectly meet your requirements. Therefore, the closed tank fermentation reactor is an ideal choice to facilitate the composting of organic waste.

Rapid composting

Composting time is something that all organic fertilizer manufacturers attach importance to.. Under natural conditions, composting organic waste takes 2 has 3 month. How to quickly break down organic fertilizer ? You can directly choose our organic fertilizer fermenter. By using it, you can complete the organic manure sanitation process by 10 has 20 days. Indeed, this composting machine generally prepares organic litter into compost in a closed environment, which isolates external influence, like the seasons, extreme weather conditions, etc.

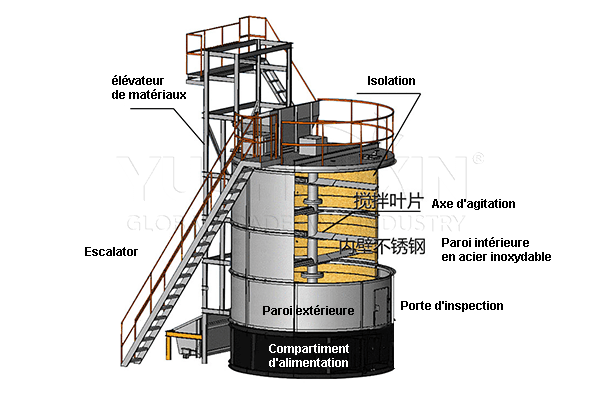

What materials are used for the insulating layer of the fermentation reactor ?

The insulating layer of closed composting equipment is crucial for maintaining stable internal temperatures during fertilizer composting. Commonly used insulation materials include polyurethane foam (PU), mineral wool and expanded polystyrene (EPS). In general, YUSHUNXIN closed tank composting machine adopts polyurethane foam, which has excellent thermal insulation, lightness and resistance to humidity. However, if you need to replace it with mineral wool or expanded polystyrene, we can also provide you with a tailor-made fertilizer fermentation reactor. At the same time, the inner and outer layers will be made of stainless steel.

Fully automatic composting system

When you want to improve the efficiency of composting organic waste, the best solution is to purchase a fully automatic composting system. Ici, the closed tank composting system is the optimal option for you. It adopts computerized control system, which operates the entire aerobic fermentation process without worker intervention. This includes ventilation, the mixture, temperature control, oxygen supply, deodorization, emptying, etc. So, it only takes 1 has 2 operators to feed the machine, and it can transform a large amount of organic litter into fertilizer compost.

Low space occupancy composter

The organic fertilizer fermenter is also the first choice for those who only have a small area for composting manure. Whether it is a pit composting machine or a windrow composter, a larger surface area is required for disposal of organic waste. However, our closed tank composting facility only requires 10 has 30 m² to carry out the fermentation of 5 has 102 m² of organic waste.

Environmentally friendly fermentation

What's more, in the composting process of organic fertilizers, you should also pay attention to the treatment of residual gas. In order to meet international environmental protection requirements, we specially equip our closed tank composting equipment with a water spray tower and an activated carbon box. They can absorb NH3, H2S and other harmful gases produced by fertilizer fermentation to prevent air pollution. Therefore, to produce compost from organic waste without pollution, organic fertilizer fermentation reactor is your best option.

Top 4 types of in-tank composting machines for animal waste disposal

In general, different fertilizer suppliers have different requirements for composting machines, because there are disparities in their composting conditions. For example, depending on the type of material, it could be chicken manure, de bouse de vache, pig manure or goat droppings ; depending on capacity, composting can be done on a small scale, medium or large scale. This is why we design various in-tank composting plants for your choice.

In-tank composting machine for small farm pig manure

Is there an organic fertilizer fermenter suitable for manure removal from a small pig farm ? Of course. You can choose our horizontal fermentation tank, d’une capacité de 5 at 50㎡. This means that it can treat 5 has 50 tons of pig manure per batch, with a moisture content of 50 % has 70 %. What's more, as a horizontal fermentation tank only covers a surface area of 10 at 30㎡, you can use it to directly transform piggery waste into organic fertilizer compost on a small scale on your farm.

| Model | SXWFT | Puissance de la pompe à huile chaude (KW) | 1.5 |

| Engine power (kW) | 18.5 | Puissance du groupe hydraulique d’admission (KW) | 0.55 |

| Puissance de la tige chauffante (kW) | 3*10 | Puissance du groupe hydraulique de sortie (KW) | 0.55 |

Fermentation tank for composting manure 50 000 poules

If you own a poultry farm of less than 50 000 poultry, nous vous recommandons notre cuve de fermentation SXFT-30. Indeed, one hen produces approximately 0,15 kg of droppings per day. 25 000 hens thus produce approximately 7,5 tons of manure per day (teneur en humidité : environ 75 %). La cuve de fermentation SXFT-30 peut traiter 5 has 8 tons of chicken manure, with a moisture content of 50 % has 70 %. It is therefore an ideal choice. In general, it allows us to produce 2 has 3 tons of chicken droppings compost, the moisture content can then be reduced to 30 %.

102㎡ tank composting equipment for cow manure for sale

But when you want to compost cow manure, it is necessary to acquire a larger capacity organic fertilizer fermenter. Nous vous proposons ici la cuve de fermentation en cuve SXFT-100, with a capacity of 102㎡. In general, she can treat 8 has 12 ㎡ of livestock manure per day, with a moisture content of 50 % has 70 %. After composting, you can get 4 has 5 ㎡ of fertilizer compost per day. Can it compost dairy manure with moisture above 70 % ? In this case, you can use manure dehydration machine to remove excess water from cow manure.

Fermentation tank for large-scale goat manure processing

Can an in-vessel composting facility treat 50 tons of goat droppings per day ? In general, you can achieve this large-scale composting in two ways. On the one hand, you can directly increase the number of fermentation tanks. On the other hand, you can contact us for customization service. Whatever method you choose, we will design the best solution for composting organic matter based on your actual conditions.

| Model | Puissance de chauffage (kw) | Puissance de brassage (kw) | Matériel entrer | Dimensions |

|---|---|---|---|---|

| SXFT-10 | 4 | 11 | belt conveyor | 2400x2400x6900 |

| SXFT-20 | 4 | 18.5 | belt conveyor | 3100x3100x6500 |

| SXFT-30 | 4 | 7.5 | Feeding bucket | 4000x4000x7000 |

| SXFT-100 | 4 | 7.5 | Feeding bucket | 5000x5000x8500 |

How much does an in-tank composting system for organic fertilizer cost? ?

When you want to buy an organic fertilizer fermenter, price is something you need to pay attention to. The cost of fertilizer composting equipment is influenced by many factors, especially the configuration. Our in-vessel composting facility adopts many advanced technologies, which promote better composting of organic waste. For example : temperature monitoring, oxygen control, double isolation, exhaust gas treatment system, fully automated control, etc. Therefore, when you plan to start in-vessel composting, you must plan between 19 000 $ et 180 000 $.

What is the process of in-vessel composting system ?

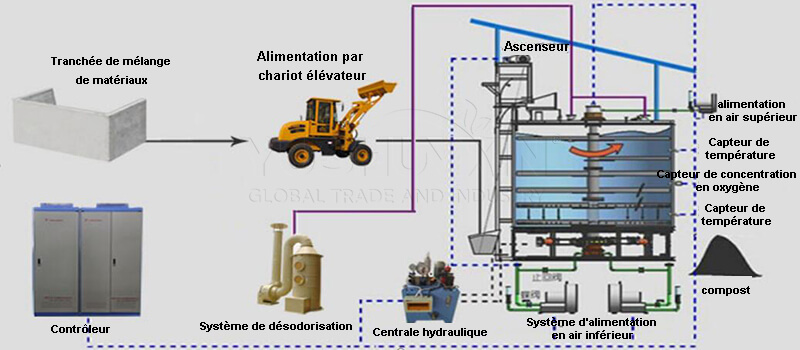

In general, the in-vessel composting process has three parts : mixing and feeding materials, composting of fertilizer and unloading of composted organic fertilizer as well as treatment of waste gases.

Mixing of materials and feeding

The composting process in an organic fertilizer fermenter begins with mixing the materials. Livestock manure and agricultural residues are mixed with fermentation agents to obtain an optimal carbon/nitrogen ratio and accelerate the production of compost. For that, twin shaft mixer and chute mixing are ideal choices. A forklift then transports the prepared mixture to the in-tank fermenter. Thanks to a lifting and hopper feeding mechanism, the materials are loaded into the composting tank.

Composting and aeration control

Inside the in-tank composter, an internal mixing shaft rotates to maintain even distribution and aeration. The air supply system introduces oxygen, while the temperature and oxygen sensor system continuously monitors composting conditions to support thermophilic microbial activity. This precise control guarantees the destruction of pathogens and accelerates the decomposition of the organic fertilizer.

Unloading and odor management

Once composting is complete, the discharge system discharges the finished composted fertilizer. You can choose to sell it directly or process it into powdered or granulated organic fertilizer. As for waste gases, an odor treatment system based on activated carbon and water spray is also available, guaranteeing compliance with environmental regulations.

With these built-in features, in-tank composting systems allow you to quickly prepare fertilizer compost without any hassle.

How to further transform compost into organic fertilizer ?

If you want to increase your profits, you can turn compost into organic fertilizer. In general, after composting in tanks, you can choose to produce two forms of organic fertilizer : powdered organic fertilizer or granulated organic fertilizer. For that, we can provide professional organic fertilizer manufacturing plans.

Powdered organic fertilizer manufacturing plan

If you want to transform compost into organic fertilizer in a simple way, it is ideal to produce powder fertilizer. All you need is a charger, of a crusher, of a powder screening machine, packaging equipment and a conveyor to transform the compost into quality powdery organic fertilizer. This method has advantages such as low investment, reduced space and easy handling. It is therefore the most profitable organic fertilizer production line on the market.. For example, to acquire a powder fertilizer production system 1 has 2 t/h (including composter), just plan 35 000 $ and a surface of 800 ㎡.

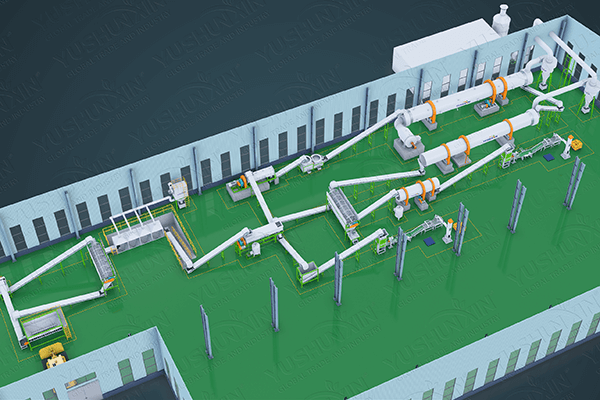

Granulated organic fertilizer production line

For those who wish to improve the quality of fertilizer produced from compost, we have also designed a granulated organic fertilizer production line. Compared to powder fertilizer production, it involves a more complex process. In addition to the composter, it also requires a weighing machine, a grinder, a mixer, a granulator, a sieve, a dryer, a cooler, a coater, a pellet bagger and a conveyor. This equipment makes it possible to transform compost into quality granulated organic fertilizer, more competitive on the market. Indeed, granulated fertilizer is easier to transport, store and use. So, this fertilizer manufacturing system can generate profits in less than a year.

In addition to the in-tank composter for rapid composting of manure, we also design many other machines for fertilizer decomposition, such as economical pile turning composter or ferris wheel composting equipment. Do not hesitate to contact us to develop your fertilizer business plan now !