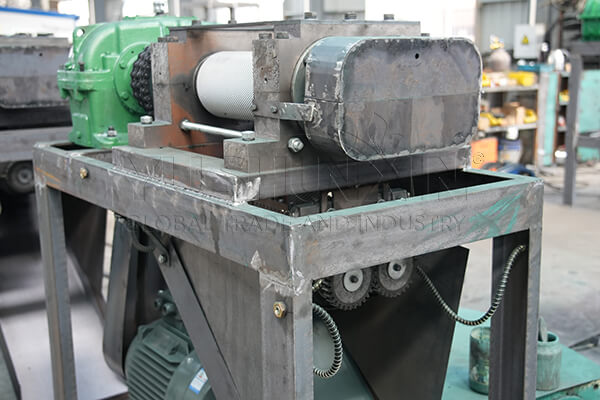

Double roller granulator is favored by many fertilizer manufacturers, especially for NPK pellet manufacturing plants. Indeed, it allows fertilizer granulation to be carried out quickly with a low investment. This machine adopts dry granulation method, which mainly uses the physical extrusion force between two rollers to transform the chemical powder into granules. What's more, if you want to launch an organic fertilizer granulation project, this equipment can also fully meet your needs. In addition to the double roller granulator, We can also provide you with the corresponding equipment to form a complete industrial double roller granulation line for fertilizer manufacturing.

Settings

- Ability: 1 at 4 t/h

- Feed humidity: 5 at 20%

- Pellet size: 3 to 10 mm

- Granulation rate: 97 %

- Equipment material: Q235 carbon steel + 20CrMnTi or 4Cr13

- Application: Production of pellets from powdered dried manure, nitrogen fertilizer, phosphate fertilizers, de bentonite, industrial salt, etc.

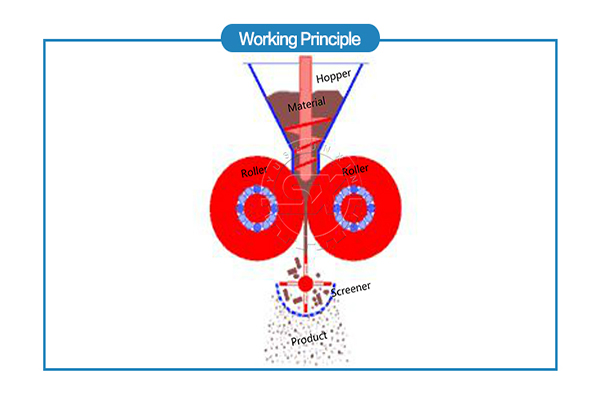

What method does the double roller extrusion granulator adopt to make fertilizer granules ?

Are you interested in double roller granulator ? Do you want to use it in your fertilizer production project ? It is first necessary to understand the granulation method it adopts.

This granulation equipment uses dry granulation method, which almost directly transforms the chemical material into granules without adding water. It mainly relies on the extrusion force between the two rollers to granulate the compound fertilizer. The moisture content of the raw material must be less than 10 %. In this way, there is no need for subsequent drying or cooling. You can therefore finalize the manufacturing of compound fertilizer granules by a simpler and lower cost process.

| Model | Power (kW) | Granule diameter (mm) | Roll dimensions (mm) | Dimensions (mm) |

|---|---|---|---|---|

| SXDG-1T | 15 | 3-10 | 150×220 | 1450×800×1450 |

| SXDG-1.5 T | 18.5 | 3-10 | 150×300 | 1450×850×1500 |

| SXDG-2T | 22 | 3-10 | 185×300 | 1630×850×1650 |

| SXDG-2.5T | 22 | 3-10 | 245×220 | 1700×1000×1670 |

| SXDG-3T | 30 | 3-10 | 200×400 | 1960×980×1760 |

| SXDG-4T | 37 | 3-10 | 250×400 | 1960×980×1760 |

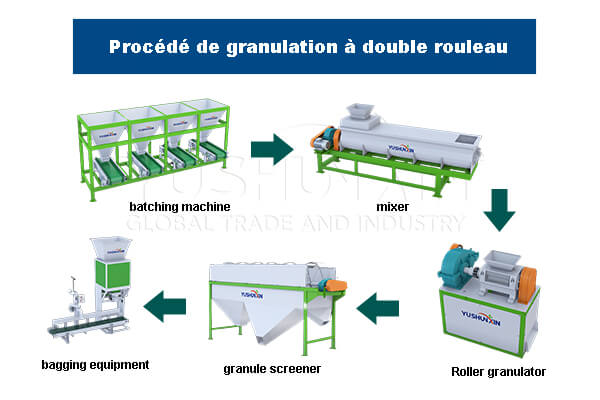

What is the design of roller press dry granulation line ?

As mentioned above, double roller granulator adopts dry granulation method, which avoids the use of a dryer and cooler. So, for the manufacture of NPK granules, the system generally includes 6 machines :

- Dosing machine : precise feeding of raw materials according to the formula.

- Crushing equipment : grinding of NPK material into fine powder, which facilitates granulation by rollers.

- Blender : homogeneous mixing of NPK powder to guarantee nutrient balance in the final granules.

- Double roller granulator : rapid pressing of dry NPK powder into fertilizer granules.

- Tamis : separation of NPK granules of the desired size, with return of small and large granules for re-treatment.

- Packaging scale : bagging the final NPK granules according to the required weight (10 kg/sac, 20 kg/sac, 50 kg/sac, etc.).

Top 2 double roller granulation systems with capacity of 1 has 20 t/h

In general, there exists 2 Types of Double Roller Granulation Systems Most Purchased by Granulated Fertilizer Manufacturers : A small-scale fertilizer pellet production line 1 has 4 t/h. A roller extrusion system 4 has 20 t/h for large-scale granulation.

Small Scale Fertilizer Pellet Production Line 1 has 4 t/h

If you are planning to launch a small scale fertilizer pellet production project with capacity of 1 has 4 t/h, all you need is one double roller granulator.

YUSHUXIN can offer you models of 1 t/h, 1,5 t/h, 2 t/h, 2,5 t/h, 3 t / h and 4 t/h. As for the complete fertilizer granulation line, it includes the following equipment :

- Static Dosing Machine

- SXFLF-600 vertical crusher (3-5 t/h)

- Double shaft mixer

- Roller granulator

- SXGS-1240 Rotary Screen (3-5 t/h)

- Single Bucket Bagging Machine

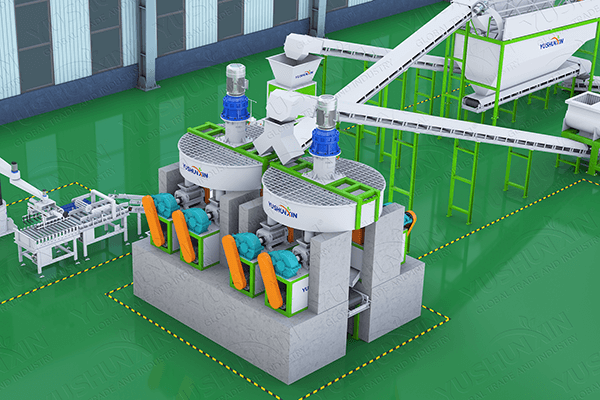

Roller extrusion system 4 has 20 t/h for large-scale granulation

For a fertilizer pellet production project of more than 4 t/h, you can combine 2 roller granulators or more. In this case, a disc distributor allows the mixed powder to be evenly distributed to the roller granulators.

So, it is possible to fully meet your fertilizer pellet manufacturing needs 4 has 20 t/h. In parallel, you can replace other machines with large capacity models. For example :

- Machine de dosage dynamique

- Broyeur vertical SXFLF-1000 (10-15 t/h)

- Mélangeur horizontal

- Granulateurs à extrusion à rouleaux

- Tamis SXGS-2080 (10-20 t/h)

- Machine d’emballage à double godet

3 characteristics of fertilizer granules under double roller granulation

But the most direct and effective way to choose a suitable granulating machine is to test the final fertilizer granule. SO, what kind of NPK granule can the double roller granulator produce for you ? In general, the double roller granulator presents 3 highlights as follows :

Production of fertilizer pellets 3 has 10 mm

What is the size of the final granules produced by a double roller granulator ? This is a criterion to which most fertilizer manufacturers attach importance. En règle générale, our double roller granulator can prepare compound fertilizer particles with a diameter of 3 has 10 mm. It can fully meet your needs.

How to adjust pellet size during double roller pelletizing ?

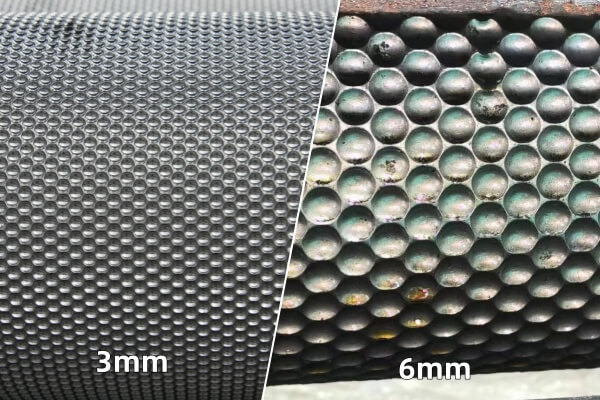

Using the dry granulation method, fertilizer granule size is generally not influenced by humidity. SO, what is the determining factor for the size of pellets obtained by double roll extrusion ? This is the size of the cavities on the two rollers. Donc, when you want to regulate the size of your compound fertilizer granules, the best solution is to use rollers with cavities of the desired size.

Various shapes to choose from

Besides the size of the cavities on the rollers, you also have a wide range of options regarding the shape. For the shape of the cells of the roll sheet, we can make pincushion shapes, semicircle, stick, compressed, nut, flattened ball or square bar according to your requirements. So, whether you want to produce oval fertilizer granules, irregular, shaped like a grain of wheat or other shapes, you can do it easily and quickly.

Can fertilizer granules obtained by roller press be transformed into round balls? ?

Of course. Just add fertilizer polishing machine after roller granulators. This machine uses multiple polishing to make the pellets more round and uniform in size.

High hardness

What is the difference between fertilizer granules from double roller granulation and those obtained with a disc granulator or rotary drum pelletizer? ? The most obvious difference is hardness. The double roller granulator can offer NPK compound fertilizer pellets or snow melter pellets with higher hardness than produced by other chemical pelletizing equipment. The hardness can reach 10-52 N, which means your final compound fertilizer granules have a low probability of spraying and are more convenient to transport, store and use.

What are the advantages of using a double roller granulator in a fertilizer granulation system? ?

Large application

Whether you want to produce 20-20-20, du 20-10-10 or other NPK fertilizer granules. Whether you are considering preparing special compound fertilizers with high, medium or low concentration. Double roller granulator can fully meet your needs. And the quality of final granules conforms to the technical requirements of compound fertilizers.

Capabilities of 1 has 20 TPH

To meet the different capacity requirements of fertilizer manufacturers, we have specially designed various models of double roller granulating machines. SXDG-1T, SXDG-2.5T, SXDG-4T, etc. If you want to start compound fertilizer granulation on a small scale with production of 1 has 20 t/h, these are the optimal choice.

High granulation rate 95 %

Would you like to granulate powder raw materials with high efficiency ? Do you want to buy an organic or compound fertilizer granulator with a low material return rate? ? Ici, we recommend you choose the double roller granulator. Its granulation rate can reach 95 %. So, only a small amount of material needs to be returned for reprocessing. So you can produce more qualified fertilizer granules at the same time.

Cost reduced by 4 000 $ has 22 000 $

With double roller granulating equipment, you can reduce the cost on two aspects. On the one hand, it has a great price. With only 4 500 $ has 22 000 $, you can buy it. On the other hand, it reduces the cost of replacing machines. The material of double roller granulator is Q235 boiler steel and that of rollers is 20GrMoTi or 4Cr13 stainless steel. So, by simply changing the rollers every six months, you can keep this machine working for a long time.

What type of fertilizer can the double roller granulator produce ?

If you want to know if the double roller granulator is suitable for you, you need to check if it can produce the fertilizer you want. In general, it is suitable for the following situations :

Manufacturing of NPK compound fertilizers

To provide a balanced supply of nitrogen, du phosphorus and potassium to crops, it is essential to transform NPK fertilizer into pellets. Ici, double roller pelletizing equipment is an ideal choice. Whether you want to prepare NPK fertilizer granules 20-20-20, 20-10-10 or other formulas, it can complete the task quickly and easily.

Granulation of fondant for snow

Double roller granulator is also widely used in the manufacture of snow removal agents. Because after granulation, the product is not only more effective, but also easier to pack, transport and store. What's more, using this extrusion machine, you can turn the snow removal agent into pellets at a lower cost.

Can the double roller granulator make bentonite or organic fertilizer granules ?

Of course. As long as the moisture content of the materials is less than 20 %. Many powders can be processed into fertilizer granules with the roller granulator. Including compost in organic fertilizer granules, production of bentonite cat litter pellets, carbon black granulation, etc.

If you want to get more information about double roller fertilizer granulation, do not hesitate to contact us now ! Furthermore, there are also many other fertilizer granulation processes available to you. Comme la ligne de granulation humide à disque, the rotary drum pellet production on a large scale, etc.