For those who wish to invest in a $300,000 budget unité de production d’engrais NPK, our engineers have three solutions to offer you. The best choice is disc or drum granulating line, which makes it possible to manufacture quality NPK fertilizers. What's more, for areas without water, we offer dry roller granulation system. Si vous vous concentrez sur les bénéfices et le retour sur investissement de votre projet de production d’engrais NPK. Nous pouvons également vous fournir des plans d’affaires pour des bénéfices élevés et un retour sur investissement rapide. Please feel free to contact us to get your own NPK fertilizer production line.

Settings

- Ability: 15 at 40 t/h

- Cost: $300 000 -400 000 $

- Products: pellets, BB fertilizer

- Equipment material: Q235 carbon steel, stainless steel

- Application : NPK fertilizer manufacturing, production d’engrais composés

How to make NPK pellets on a budget of 300 000 $ ?

If you plan a budget of 300 000 $ for the purchase of NPK pellet manufacturing machines, we recommend you choose disc pelletizer line or rotary drum pelletizing system. Both of these methods use wet granulation, which allows NPK powder to be quickly granulated using liquids. What's more, they can produce between 1 et 10 tons of NPK fertilizer per hour without difficulty.

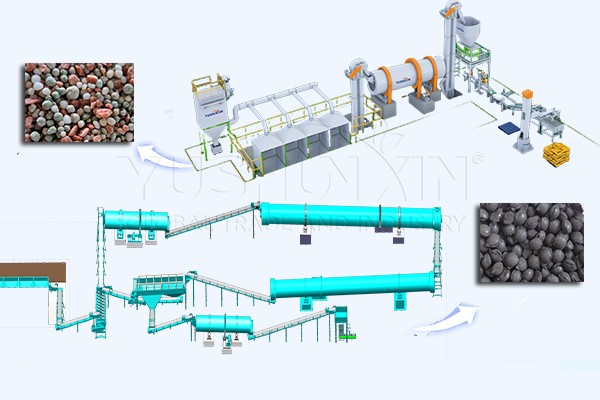

Large capacity rotating drum NPK granulation line

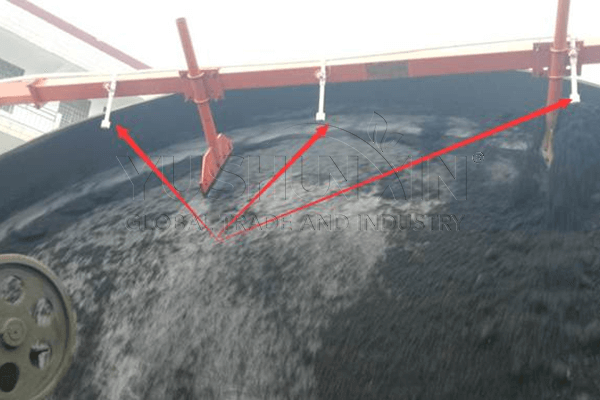

If you are planning an investment in a $300,000 NPK fertilizer production unit budget with high production, as 15 T/h, the rotating drum granulation line is the best choice. This line only requires one drum granulator during the whole process. What's more, compared to other NPK pellet machines, it is equipped with an additional rubber coating that reduces erosion caused by large-scale NPK fertilizer manufacturing.

NPK disc granulation plane with a granulation rate of 93 %

However, if you need a higher granulation rate in NPK pellet manufacturing, it is advisable to opt for a disc granulation system. Thanks to the rotation of the disk and the cohesion of the liquids, the granulation rate of your NPK granules will be greater than 93 %. In general, the maximum capacity of a disc pelletizer is from 6 T/h. So, to set up an NPK granulation line 10 T/h, you will usually need to purchase 2 SXYZ-3600 disc granulator sets.

To help you produce NPK fertilizer smoothly, we can provide you with disc pellet machines and rotary granulators with liquid spraying device. So, you can precisely add liquids or water to maintain the humidity of the NPK materials between 20 et 45 %. At that moment, NPK powder will quickly turn into fertilizer granules.

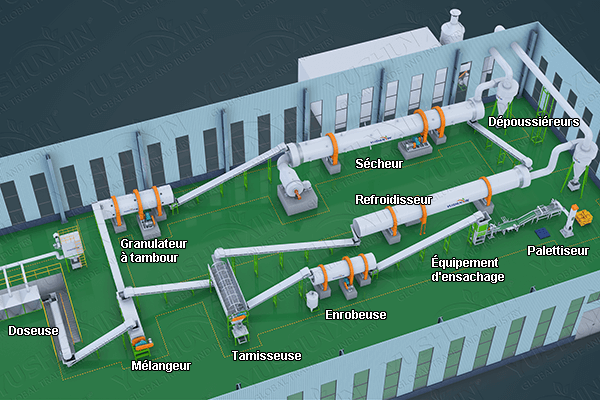

What equipment is needed in NPK pellet manufacturing solution of 300 000 $?

Due to the use of wet granulation method, NPK fertilizer production line generally includes 9 steps :

- Dosing machine fertilizers to feed powder materials N, P, K according to the formulation.

- NPK crusher to grind materials into a size of 0,3 has 0,5 mm, facilitating the formation of NPK granules.

- Double shaft mixer for uniformly mixing powder materials N, P, K.

- Ensuite, the equipment of granulation disc or drum will process the NPK powder mixture into granules of required size.

- Sieving NPK fertilizer granules to obtain uniformly sized granules.

- Drying NPK fertilizer particles after sieving to reduce moisture to less than 10 %.

- Cooling NPK fertilizer granules to lower the temperature resulting from drying.

- Finally, packaging NPK fertilizer granules in bags of 5 kg, 10 kg, etc., for storage and sale.

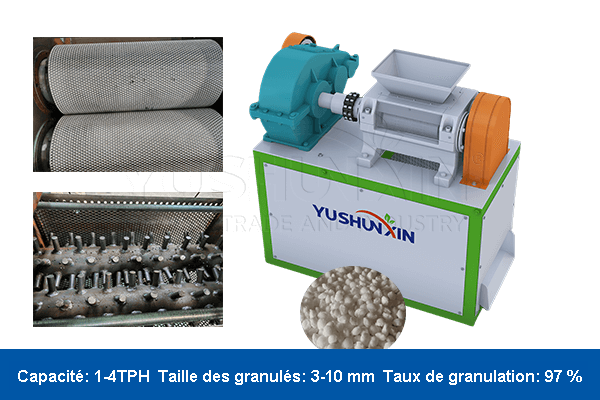

Can a dry roller granulator be used in a $300,000 budget unité de production d’engrais NPK?

Of course. For a dry NPK fertilizer production project, we have specially designed a double roller granulation line. Ici, roller granulator mainly presses NPK materials between two rollers to make them into fertilizer granules. What's more, the humidity of the materials to be fed must be less than 10 %. It is therefore the best choice for making NPK fertilizers without water.. At the same time, you can reduce the costs of drying and cooling NPK fertilizer granules.

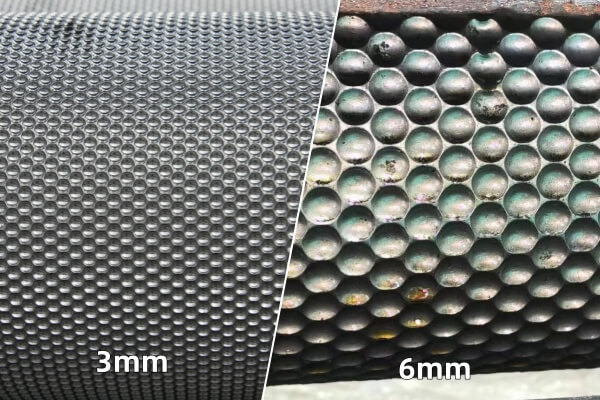

In general, an extrusion granulator can produce 1 has 4 tons of NPK granules per hour. To achieve a production of 15 T/h, you just need to use more roller pelletizing machines. To produce NPK pellets at a capacity of 15 T/h, environ 4 sets will be needed. What's more, according to your needs, we can customize rollers based on material or size, like the alloy in stainless steel 4Cr13 and for the manufacture of NPK granules 3 mm, 4 mm, 5 mm, etc.

Can you provide us with a business plan for the production of NPK fertilizer with a cost of 300 000 $ ?

If you want to make more profits with NPK fertilizer manufacturing, we also have the best NPK fertilizer production line at a budget of 300 000 $ for you. In this case, you can buy two different types of NPK fertilizer production lines : One is the NPK granulation line mentioned above, the other is a bulk fertilizer mixing system.

NPK granulation line

The first helps you prepare high-quality NPK fertilizer pellets, which generate more profits. You can buy an NPK granulation line with a capacity of 5 T/h, whose price varies between 120 000 $ et 170 000 $.

Mixed NPK fertilizer system

The second allows you to produce mixed NPK fertilizers, using a three-step method : the dosage, mixing and packaging N granules, P, K. With an investment of only 100 000 $, you can produce between 20 et 30 tons of NPK fertilizer per hour.

So, your NPK fertilizer plant will be able to meet the needs of high-end market and low-end market, thus offering a better return on investment for your NPK fertilizer production line at a cost of 300 000 $.

As a professional fertilizer equipment manufacturer, YUSHUNXIN makes every effort to offer you the best business plans for fertilizer manufacturing. For example, we also design NPK fertilizer manufacturing plants to suit other budgets, such as NPK fertilizer plant projects in 50 000 $, 100 000 $ and NPK fertilizer manufacturing solutions 500 000 $, etc. If you have other needs about fertilizer production lines and machines, do not hesitate to contact us immediately.