Dans le organic fertilizer manufacturing process, humidity to make organic fertilizer usually plays an important role. Too much water or too little water will affect the quality of organic fertilizer production, particularly in the composting stages, granulation and bagging. SO, what is the humidity level required in the manufacture of organic fertilizer ? YUSHUNXIN provide the correct answer here.

What is the ideal humidity for composting organic fertilizer?

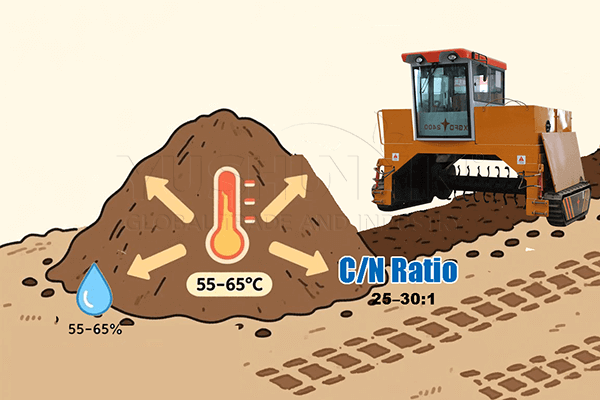

When you want to produce quality organic fertilizer, it is essential to compost raw materials. Because composting is a process that eliminates harmful substances contained in organic waste. But if you want to speed up the composting of organic waste, humidity control is something you need to focus on.

Excess water (more than 60 %) blocks oxygen transport, essential for the aerobic fermentation organic waste. While too low a water content (less than 40 %) does not allow the activity of composting bacteria. It is therefore advisable to maintain the humidity of the materials between 40 % et 60 %.

How to reduce humidity for decomposition of organic fertilizers

In general, two solutions are available to you.

- On the one hand, spread dry materials under composting piles, such as straw, the leaves, corn cobs, etc. On the other hand, directly use a dehydration machine.

- This makes it possible to quickly eliminate the water contained in the organic matter intended for the production of fertilizers. After dehydration, humidity may decrease 30 %-40 %.

What water content is required for granulation of organic fertilizers

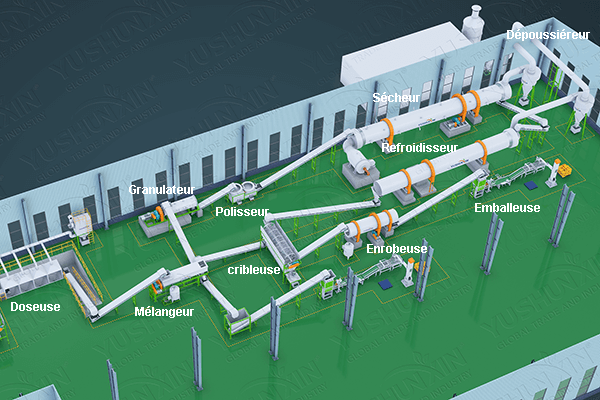

In order to successfully transform compost into organic fertilizer granules, it is also necessary to control the water content before granulation. SO, what is the optimal moisture content of materials when feeding for granulation ? 20 %-40 %.

But how to adjust the humidity for better granulation ? In general, no additional action is necessary. For what ? Because composting causes a rise in temperature, which causes continuous evaporation of water. After composting, the humidity of organic matter is approximately 30 %, what is suitable for making fertilizer granules.

How to increase humidity during granulation of organic fertilizers

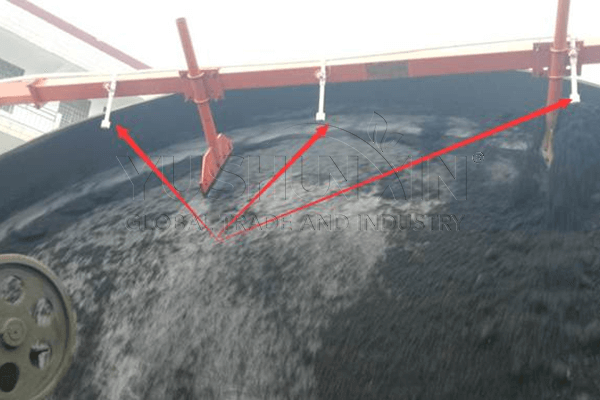

In addition to water reduction, it is sometimes necessary to increase humidity when making organic fertilizer granules. How to achieve this ? To add water easily, we have specially designed spray devices for disc granulator and granulateur à tambour rotatif. But how to increase humidity when using other pelletizing machines ? You can choose to add water when mixing fertilizers.

The final moisture standard before packaging organic fertilizers

Finally, you need to adjust the final moisture of the organic fertilizer to less than 10 % before packaging. There are two reasons for this.

- On the one hand, for the production of organic fertilizer granules, plus l’humidité est basse, the higher the hardness, less risk of spraying, and the easier transportation is.

- On the other hand, low humidity prevents fertilizer from molding and going bad. So, the fertilizer you produce can be stored longer.

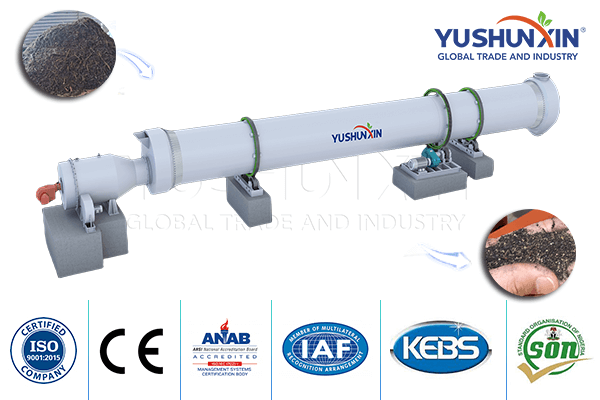

How to regulate fertilizer moisture before packaging

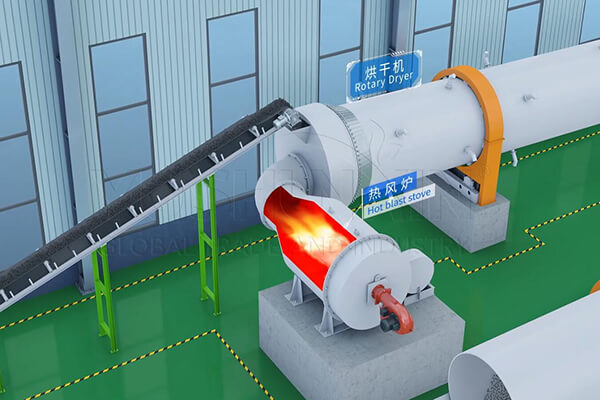

Ici, if you want to dry the fertilizer quickly and easily, il est conseillé d’utiliser un séchoir rotatif, which plays an important role in drying fertilizers. During operation, the hot air in the drum can reach 300℃. Therefore, this machine can reduce your organic fertilizer to less than 10 % humidity in a short time.

We also offer many other solutions for the production of organic fertilizers, such as compost management, the duration of composting, the granulation rate, etc. We also offer tailor-made fertilizer solutions for you !