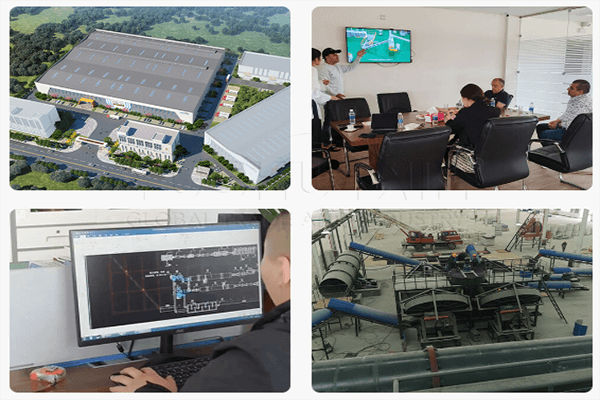

When you want to set up a commercial scale NPK fertilizer plant, a reasonable disposition plan is essential. This not only makes it possible to make the NPK fertilizer production more fluid, but also to reduce the manufacturing cost of NPK compound fertilizers. Ici, YUSHUNXIN fertilizer equipment factory can help you greatly. We provide you with the division of zones, the drawing of the NPK fertilizer production line, suitable equipment, the necessary surface area, etc. What's more, If you have other requirements for NPK fertilizer plant layout plan design, you can also contact us for customized solutions.

Top 3 Considerations for NPK Fertilizer Plant Layout Plan Design

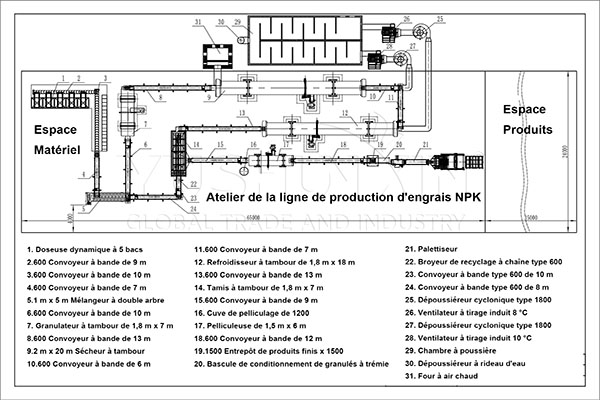

For the design of the NPK fertilizer plant layout plan, it is necessary to know how many parts it contains. In general, it consists of at least three zones : the raw materials area, NPK fertilizer manufacturing system workshop and NPK fertilizer finished product storage area.

Raw materials area

Usually, raw materials for the preparation of NPK fertilizers are of three types : powdered chemical materials, compound fertilizer granules and ores. To avoid excessive humidity, it is advisable to keep chemical materials indoors. But sometimes, this is not possible, especially in large-scale production of NPK fertilizers or when using ore as raw material, like the phosphate rock. In this case, you can build a shed for outdoor storage (as shown below). Ensuite, you can choose our wet granulation granulator, which requires a water content of the materials of 20 % has 40 %, such as the disc granulator or the granulateur à tambour rotatif.

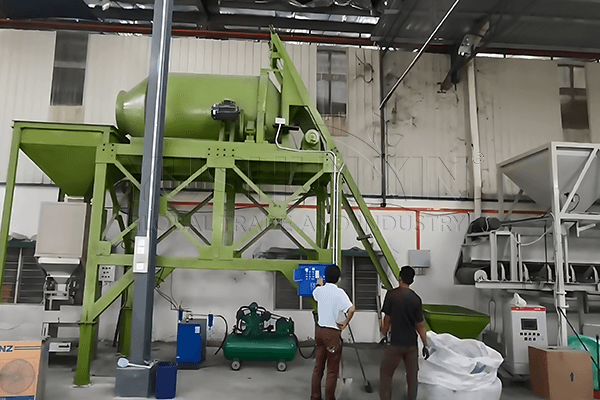

NPK Fertilizer Production Line Workshop

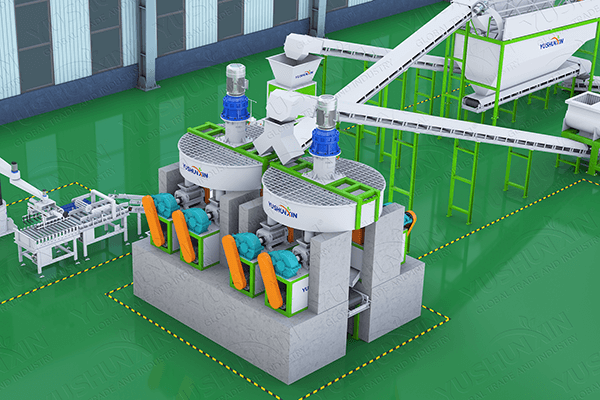

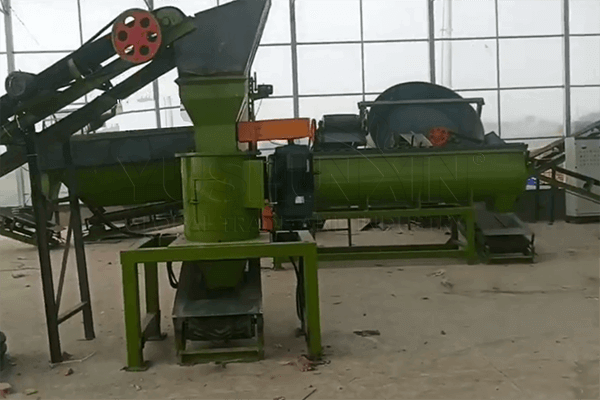

In an NPK fertilizer factory, one of the most important areas is the space for production line equipment. For that, we recommend that you build a workshop to accommodate them. This reduces the external influence of rain, snow, strong wind, etc. on your NPK fertilizer production process. So, you can prepare compound fertilizers more easily and more stable.

Storage area for finished NPK fertilizer products

Finally, you also need to arrange a storage area for the finished NPK chemical fertilizers you produce. Because after manufacturing, it is impossible to transport and immediately sell fertilizers every time. Therefore, you must have at least one place to temporarily store finished NPK fertilizers.

How many areas does an NPK fertilizer manufacturing plant cover? ?

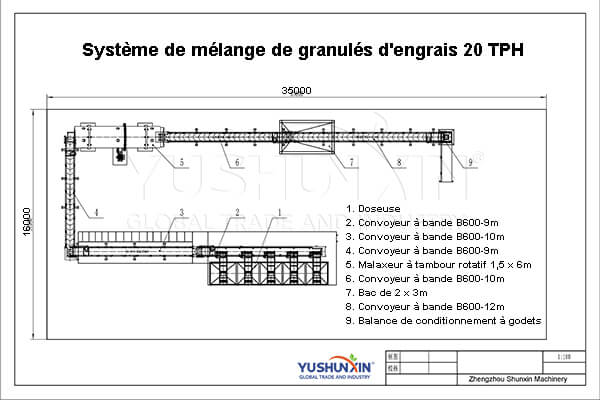

In addition to the functional division of zones, it is essential to know the surface area occupied in the NPK fertilizer plant layout plan. Raw material area and finished product area are directly related to production capacity. The lower the capacity, the smaller the surface area required. However, for the area occupied by the NPK fertilizer production line, you also need to consider the method and equipment you choose.

Development of an NPK fertilizer factory 1 000 has 8 000 m²

If you have a workshop large enough to manufacture NPK fertilizers, our NPK fertilizer granulation line is an excellent choice. In general, a complete NPK pellet production line includes a dosing machine, a crusher, a mixer, an NPK granulator, a rotary dryer, a cooler and automatic packaging equipment. Therefore, this system requires a surface area of 1 000 has 8 000 m². The precise parameters should be determined based on your ability, equipment configuration, etc.

Setting up an NPK fertilizer plant with limited area

However, if your workshop is small, you can choose powder fertilizer production line or bulk blend fertilizer line to prepare NPK fertilizer. These systems only require a few machines, but can help you finalize the production of NPK fertilizers. With less equipment, their space occupation is much smaller than other solutions.

What can YUSHUNXIN do for setting up your NPK fertilizer plant? ?

As a good partner, YUSHUNXIN can provide you with suitable equipment for the entire NPK fertilizer manufacturing process. We offer you an NPK fertilizer factory layout plan according to your actual conditions and raw material requirements, capacity, de superficie, of equipment, etc.