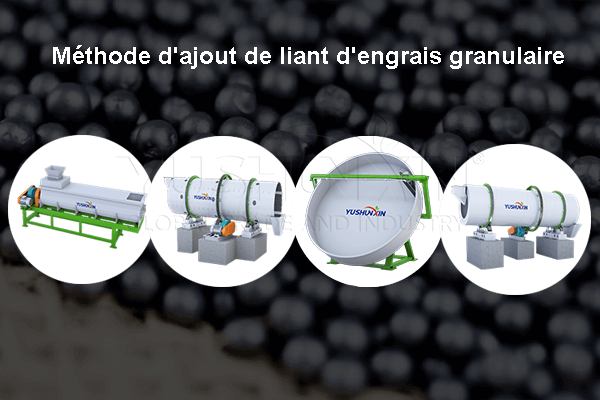

In the production of granulated fertilizers, adding granular fertilizer binders can help you obtain granules with better strength, sustainability and cohesion. However, many producers overlook the correct method and time to add these binders, which is nevertheless essential to guarantee the final result. For that, three main methods are available to you : the mixture, granulation and coating. You can choose the most suitable according to your objectives, the type of fertilizer, the granulator used and the form of the binder. Ici, YUSHUNXIN offers you personalized solutions and equipment for the manufacturing of fertilizers.

THE 3 Best Methods for Adding Granular Fertilizer Binders

In the process of manufacturing fertilizer granules, you can add three-stage granular fertilizer binders : the mixture, granulation or coating.

Mixture with binders for the manufacture of granulated fertilizers

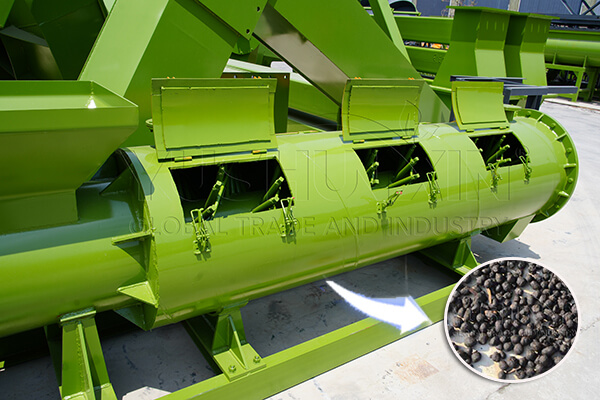

In this method, you mix the compost or chemical powder with the granular fertilizer binders evenly. So, additives can fully play their role in improving the cohesion and resistance of granules. To do this, double shaft horizontal mixer is an ideal choice. It has a professional system for adding binders, suitable for both powders and liquids, and works continuously.

Adding binders during the granulation process

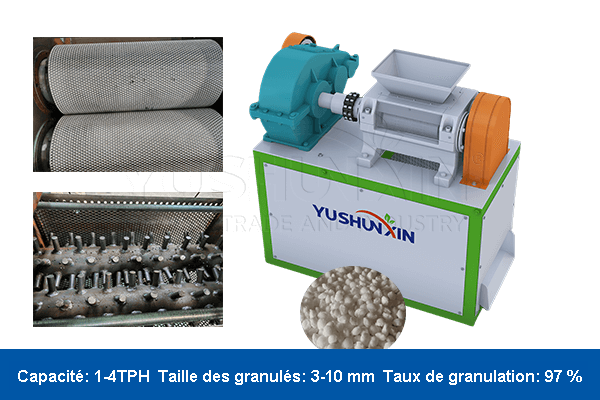

If you want to add the binders directly during granulation, there are also custom granulators. Whether you choose a disc granulator or a rotary granulator, YUSHUNXIN can provide you with these machines equipped with spraying system.

Coating granular fertilizers with binders

Furthermore, it is also possible to add additives after granulation, through the coating. For heat sensitive materials, this is the best option to avoid any degradation. YUSHUNXIN also offers rotary coating machines equipped with professional powder and liquid supply systems.

How to Choose the Best Method for Adding Granular Fertilizer Binders ?

When choosing a method for adding granular fertilizer binders, several factors must be taken into account :

Do you want to improve the strength of fertilizer pellets or speed up the process of turning powder into pellets??

Before choosing binders for granular fertilizers, it is important to understand the purpose of pellet manufacturing. Improve the strength of fertilizer pellets or speed up the process of turning powder into pellets?

- Before deciding when to add binders, it is important to define your objective in the production of granular fertilizers. If your goal is to improve hardness to avoid breakage during transportation, storage and application, it is advisable to opt for the coating, which forms a protective film.

- On the other hand, if you're just looking to turn powder into pellets faster, it is preferable to add the additives before the formation of the granules — either during mixing, either during granulation.

Make an organic or chemical fertilizer ?

The type of fertilizer produced (organic, chemical, slow release, etc.) considerably influences the choice of binder.

- In general, the manufacturing of organic fertilizers requires natural binders, such as starch, cellulose, etc. In this case, mixing them with the powder or pulverizing them during granulation are two good options.

- La chemical fertilizer production can benefit from synthetic resins or’polyvinyl alcohol (PVA), because they offer superior resistance and waterproofing. This makes it possible to produce high quality slow release fertilizer with a rotary coating machine.

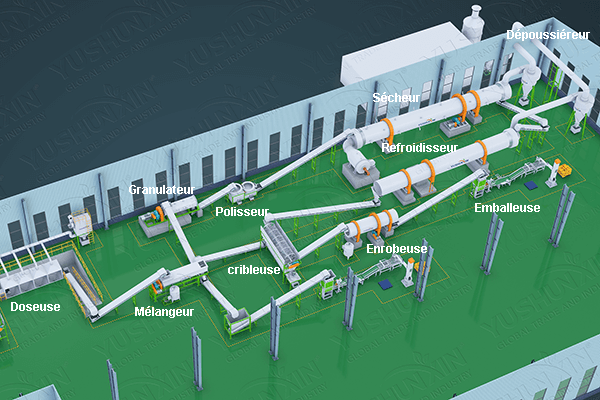

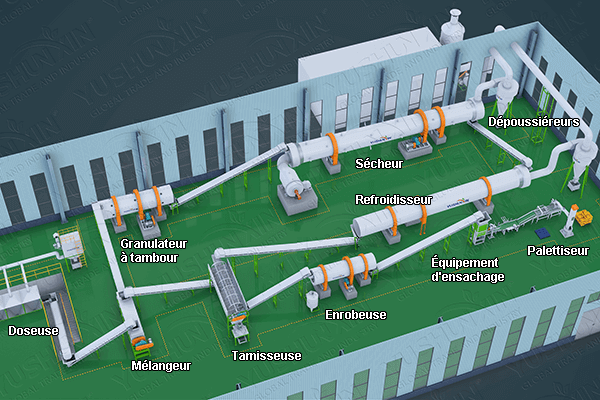

Compatibility with your fertilizer granulator

Finally, The method chosen for adding granular fertilizer binders should be compatible with the granulation equipment you are using.

- If you operate a drum pelletizing line or a disc pelletizing system, you can opt for a version equipped with a spray device.

- However, for granulators with stirring teeth or roller pellet press equipment, the best method is mixing or coating. These machines do not have space provided for an internal spray device.

Can powder binders be added for the production of granular fertilizers? ?

Of course. Whether you want to add liquid or powder binders for making granular fertilizers, there are custom systems for this. For liquid supply, a specific spraying system allows precise control of the volume of binder added. What's more, screw conveyor can be used for powder additives, ensuring precise dosing and significant dust reduction.

What granular fertilizer binders are commonly used ?

As mentioned previously, five types of binders are commonly used in the manufacture of fertilizer granules.

Starch

Source: But, potato or tapioca.

Function : Natural binder which improves the resistance and cohesion of the granules. Biodegradable, it is ideal for organic fertilizers. Starch is particularly effective when the granulation process involves slightly humid conditions.

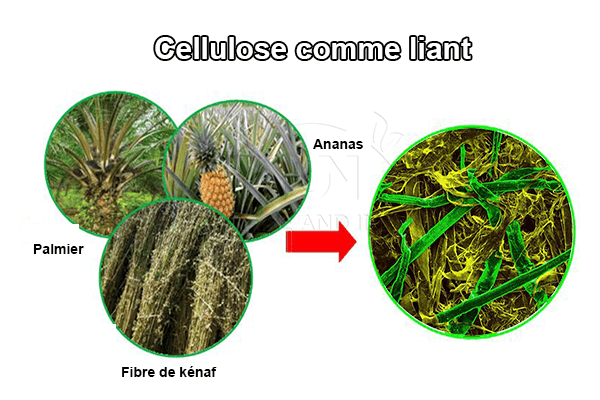

Cellulose

Source: Plant fibers.

Function : Natural binder that creates durable granules, particularly in organic or biosourced fertilizers. Cellulose helps retain moisture and improves overall pellet strength.

Polyvinyl alcohol (PVA)

Source: Synthetic polymer.

Function: PVA is very effective in creating strong, water-soluble pellets. It is often used in NPK fertilizers or other synthetic fertilizer blends. PVA offers excellent moisture resistance and durability.

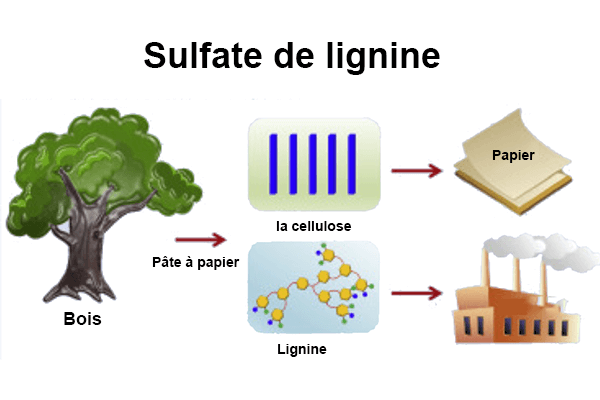

Lignin sulfate

Source: By-product of the paper industry.

Function : Ecological binder offering strong adhesion. It is often used in combination with NPK fertilizers and other compound fertilizers to improve pellet strength at lower cost..

Resins

Source: Synthetic materials, par exemple, phenolic resins

Function: Resins make it possible to produce granules that are very resistant to humidity. They are ideal for fertilizers requiring resistance to mechanical stress, like high density NPK fertilizers.

If you have anything else to know about granulation or fertilizer preparation, do not hesitate to contact us immediately.